By Clark Ricks

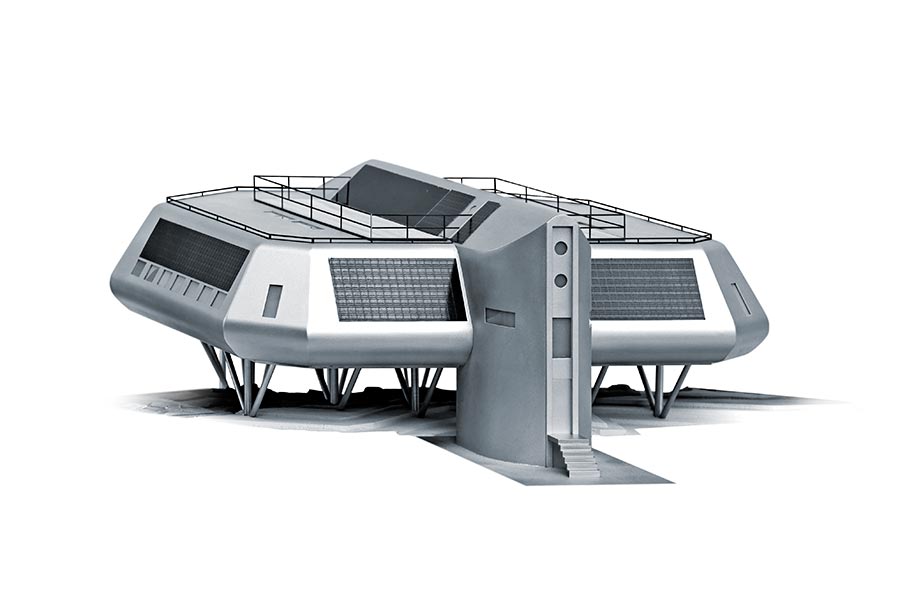

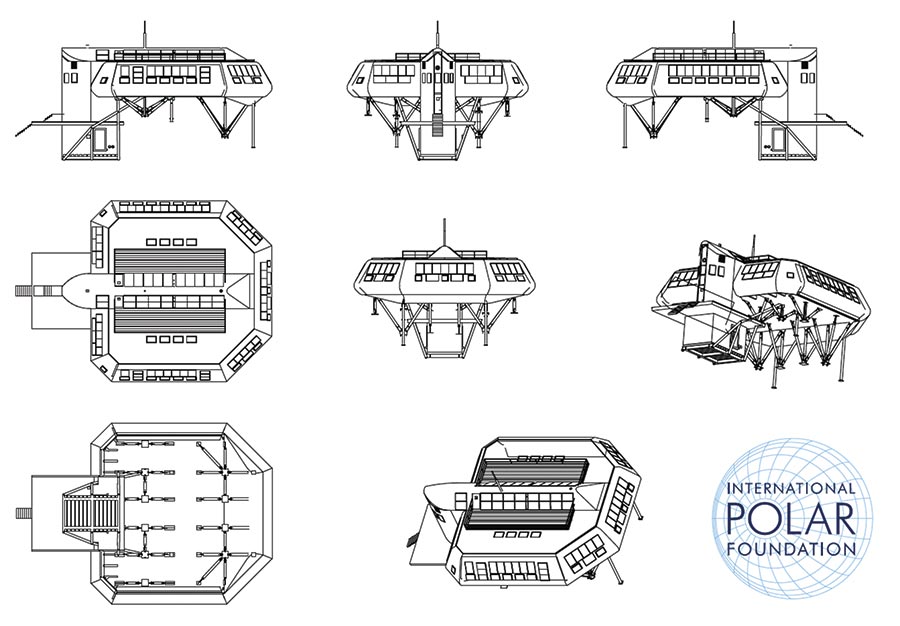

Princess Elisabeth Station is not a typical construction project. Built by a Belgian team to study the harsh Antarctic environment, it was built in one of the harshest and most remote regions of the planet.

It was also built with extremely demanding green building techniques. When construction ended in February, it became the only zero-emissions building on the continent—the first to operate without releasing any greenhouse gases.

The 20 million euro ($26 million) science station is completely energy self-sufficient, and uses micro-organisms to re-use water up to five times. Power and hot water are made possible by wind turbines on a nearby mountain and solar panels mounted on the building.

The Antarctic research station is located in Dronning Maud Land, thousands of miles south of the African coast.

Finding a long-lasting sealant that would perform in one of the planet’s harshest climates, while still meeting the zero-emissions green building standard was one significant challenge designers faced.

Scientists at Dow Corning said silicone sealants were up to the challenge. Jean-Paul Hautekeer, European construction director for Dow Corning explains, “Dow Corning silicones are virtually unaffected by weather—rain, snow, humidity, ozone, temperature variation or the sun’s damaging ultraviolet rays—and can make building what we may think is impossible, possible.”

The silicone sealant used at Princess Elisabeth research station has a proven record in extreme environments. It’s similar to the product used in the silicone rubber boots astronauts wore when they walked on the moon’s surface, where temperatures drop to -150°C.

The final phase of the station’s construction lasted a little over 4 months, and research teams will begin living there as soon as November 2009 to conduct climate change research.