Basement repair work has a number of attractive features for contractors already involved in waterproofing.

It dovetails well with existing services, and can create an additional profit center. Additionally, demand for below-grade repair work is fairly steady—and lucrative—regardless of the state of the construction industry. And lastly, thanks to new products on the market, its now relatively easy to get involved.

Andre Lacroix, president of StablWall Wall Bracing in Macedonia, Ohio, says “Not only can repair work make you more money, but it can make you more marketable.” When he tells waterproofers about foundation repair work he says the reaction is almost always same thing: “Wow, there is so much work that I have been passing up.” He adds, “People just need to take off the blinders and open their eyes to the possibilities,” Lacroix explains.

It’s a matter of helping customers solve their problems.

Finding the Cause

The most common repair issue with basements involves crack repair. But filling the crack won’t solve the problem until the contractor addresses the forces that are causing the wall to crack in the first place.

“The first step in any basement wall repair project is figuring out the cause of the problem,” says Bob Thompson, P.E. co-founder of The Reinforcer. “A big part of that is knowing what to look for and how to read a crack.”

Structural cracking can be caused by four things: hydrostatic pressure, frost, soil movement, and settlement. Whether the basement walls are made from CMU or cast-in-place concrete, contractors can identify which of these forces is causing the problem by carefully examining the shape and direction of the cracks. CMU walls are usually easier to diagnose, as they crack along the mortar joints.

Long horizontal cracks—usually a single horizontal crack in the center two-thirds of the wall—indicates pressure outside the building pushing the wall inward.

“Frost line” cracks form horizontally a short distance below grade of the frost line. The solution is to install better drainage outside the wall so water can migrate below that point without freezing.

Bowing can also be caused by hydrostatic pressure (poor drainage) and/or expansive soils. If the amount of bowing changes based on rainfall, odds are good one or both of these factors are at play.

Stair-step cracks, which extend diagonally across the wall in stair-step pattern, are much more serious. They usually indicate one part of the home has settled faster than another, which can cause major structural damage. These cracks usually start at a weak point in the wall, like a window or door opening, and run the entire height of the wall. A stair-step crack wider at the top than the bottom is a typical sign of settling.

In rare instances, the cracking may be caused by something else—tree roots, backfilling too soon, etc. It may be necessary to consult with a soil engineer or other professional to determine the cause.

Epoxy injection literally glues the wall back together.

Non-Structural Cracking

Often, the cracking is non-structural and does not affect the strength of the foundation. In these cases, simple, easy-to-use crack injection kits will solve the problem.

“Low-pressure crack injection systems are becoming increasingly popular as the method of choice to repair leaky cracks in poured found-

ation walls,” says Jay Schmid at Polygem. “The days of digging, chipping and drilling are long gone. Epoxy and polyurethane injection systems allow for the repair and waterproofing of most foundation cracks from the inside using simple hand tools.”

Epoxy literally glues cracked concrete back together to restore the structural integrity of the concrete wall, and can get into even hairline cracks. It’s perfect for fixing walls that cracked during backfilling.

Polyurethanes react with moisture to foam up and create a flexible seal inside the crack. They’re best for cracks that may move due to changing seasons and soil pressures.

Both are available in cartridge- style systems that can be used with standard caulking guns or dual-cartridge dispensing tools, and take less than an hour to apply.

(See Foundaiton Crack Repair with Low-Pressure Injection in the Spring ’08 issue)

Structural Problems

The most costly problems to resolve are those that involve differential settlement. Underpinning is usually the best solution. Many repair contractors offer some sort of underpinning work as a key part of their business.

It involves installing a system of steel, concrete or wood piers under the foundation to carry the weight of the structure.

Some contractors use traditional drilled piers, while others use push piers, helical piers, or segmented concrete pilings. Regardless of the system used, the foundation must be stabilized before further repair work is done. (For more information on piering, see Fixing Failing Poured Wall Foundations in the Spring ’08 issue)

Fortunately, very few homes will ever need underpinning.

Bowed Walls

Bowing, on the other hand, is much more common. “Most older block walls are bowed about a quarter inch in the middle,” says LaCroix. Bowing is relatively easy to fix. Steel I-Beams and earth anchors are traditionally used; state-of-the-art carbon fiber is usually faster, easier, and better looking.

The solution, as usual, depends on the severity and location of the cracks.

Steel Beams: Steel beams are one of the oldest and most reliable methods for stabilizing bowed walls. “The steel I-beam is tried and true,” says Todd Jackson at Fortress Stabilization. He points out that they work better on poured walls than masonry because beams could “punch through” the block.

Long considered the “standard fix,” this method involves anchoring a steel I-beam to the top and bottom of the wall every four or five feet. Some contractors will bolt the bottom of the beam to the floor. Others will actually jackhammer through the slab, set the beams on the footer, and then pour new concrete to anchor it into place. The top of the beam is braced off the joists.

Steel beams are a proven fix for bowed walls but they are messy to install, and reduce living space.

This is sometimes the most cost-effective solution. If the wall is tipped from the footer, or if the crack is within a few inches of the top or bottom, it may be the only solution.

It has other advantages as well. The work is done inside the basement, so it can be performed year ‘round, and in most cases, there is no digging up the yard.

On the other hand, homeowners have to deal with steel beams being carted through their home. They lose four to six inches of interior floor space for each wall that gets braced. And during construction, they have to deal with the inconvenience of jackhammer noise, buckets of concrete rubble, and dust.

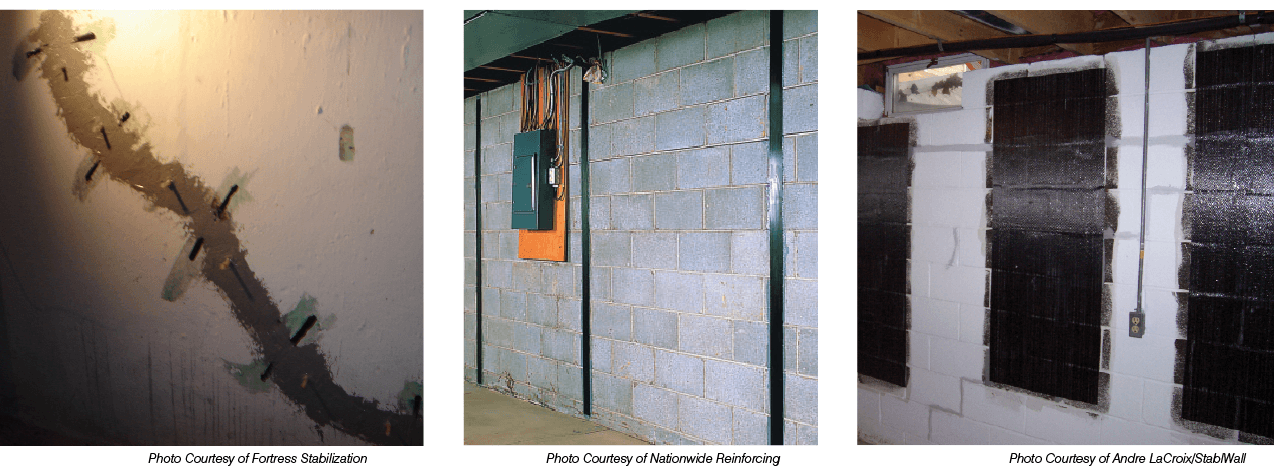

Anchors: Anchors work best for serious bows in the middle of the wall. An “earth anchor” is buried outside the home, 10 to 15 feet away from the bowed wall. Then a large threaded rod, often an inch or more in diameter, is threaded through the wall and attached permanently to the anchor. A “wall plate,” usually about two feet square, is attached to the interior end of the rod, and fastened into place with a nut.

Anchors are buried outside the home (left). Often exterior excavation will relieve wall pressure (center). A “wall plate,” usually about two feet square, is attached to the interior end of the rod, and fastened into place (right).

Sometimes, contractors excavate the soil on the outside of the wall, and can actually push the wall back to plumb by tightening the anchors.

This method doesn’t reduce room size like steel beams do, but the wall plates have to remain accessible so they can be periodically tightened. This reduces basement finishing options rather dramatically. It also assumes the lot is big enough to place the anchors in the first place.

Carbon Fiber

In the last few years, carbon fiber products have been introduced that greatly simplify the repair of bowed walls. Systems such as The Reinforcer, StablWall, and Fortress Stabilization harness the incredible strength of carbon fiber to stop wall bowing permanently. Best of all, the systems are easy-to-install, non-invasive, reasonably priced, and nearly invisible when complete.

“We wanted to come up with a carbon fiber product that would work in 95% of basements,” says LaCroix, at StablWall.

Carbon fiber works with virtually any foundation substrate, including CMU, poured concrete, and even brick and clay tile. Depending on the company, the material comes as straps, staples, or sheets.

If the bowing is not too severe, carbon fiber is likely the way to go. “As a material, it’s more expensive that steel beams,” admits LaCroix, “but factoring in the lower cost of labor, the lower overall cost of tools and manpower hours, and demand for the product,” it means more profit for the contractor at a similar price for the homeowner. You don’t need jackhammers or backhoes. There’s no crew hauling out buckets of concrete. You can work out of a pick-up.”

Carbon fiber greatly simplifies repairs. It is available in various forms including staples (left), straps (center), and sheets (right). When fastened into place with epoxy, they can be 8-10 times stronger than steel.

Fortress and The Reinforcer use carbon fiber straps. They’re about four inches wide and run the height of the room. Instead of having a wall of massive I-beams, these straps are a mere 1/8 inch thick, about the same thickness as a coin. They can be painted to match the wall, making them virtually invisible.

The key is the incredible tensile strength of carbon fiber—eight to ten times that of steel. When a foundation wall bows, the exterior face of the wall is compressed and the interior side stretches; that’s what causes cracking. Carbon fiber products keep the inside face of the wall from stretching, and if it won’t stretch, the wall can’t bow.

Stablwall makes two-foot by five-foot sheets of carbon fiber for the same purpose. Fortress makes carbon fiber/Kevlar composites and pre-shaped corner reinforcement brackets.

Regardless of the brand chosen, application is fairly similar. Determine where the straps or sheets need to be placed, then grind off all the paint, dirt, and other residue in that area to get down to clean substrate. Cracks will need to be filled with epoxy.

After the cracks are filled, apply an epoxy primer coat and carefully attach the carbon fiber product. With The Reinforcer and Fortress, that’s all that’s needed. Stablwall recommends a second coat of epoxy over the sheet. The entire process takes less than a day. And after everything has cured, it can be painted normally.

Carbon fiber does have one weakness. It has very little compressive or sheer strength, so the fibers must run perpendicular to the crack, and the crack must be filled to keep it from closing.

“The Achilles’ Heel of carbon fiber is that the contractor needs to pay attention to tuck points,” says Jackson, at Fortress. If the wall has an inch of deflection in the middle of winter, when the repair was made, and the contractor didn’t tuck point it, the wall will move backwards in the spring and the strap will bubble or pop off.”

He recommends using epoxy or mortar to fill the cracks and keep them from closing.

Waterproofing and Profits

None of the solutions mentioned above—piers, beams, anchors, and carbon fiber—is a waterproofing product. Moisture infiltration will need to be handled separately from foundation repairs.

After the carbon fiber is in place, and the wall is painted, the repair is practically unnoticeable.

However, that’s part of the allure. Structural repair contractors can be busy fixing foundations regardless of rainfall and new home starts in the area. There’s a lot of money to be made, but it’s a high-stakes game. You will be dealing with the biggest investment of your customer’s life, his home. Do the research, go to tradeshows, join contractor associations, and talk with manufacturers.

Below-grade repair work could take your company to the next level.

Fall 2009 Back Issue

$4.95

Advances in Coatings

Green Decks and Planter Boxes

Below Grade Repair Strategies

Protecting a World Class Bridge

AVAILABLE AS A PDF DOWNLOAD ONLY

Description

Description

Advances in Coatings

The new generation of spray-applied waterproofing coatings provide better protection, faster cure times, less health risks, and more durability.

Green Decks and Planter Boxes

With construction similar to vegetative roofs, green decks and planter boxes preserve open space, reduce stormwater runoff, and protect the building envelope.

Below Grade Repair Strategies

This is one area of the business that does well regardless of the economy. Crack injection, piering, and carbon-fiber products all have their place.

Protecting a World Class Bridge

One of the world’s longest bridges. Stretching 5.6 kilometers (more than 2 .5 miles), is made almost entirely of concrete.

Additional Info

Additional information

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

|---|