Waterproofers have an advantage over others when it comes to finishing below-grade space, since they know how to make the area dry and healthy. Use the right products and good craftsmanship to ensure the customer is satisfied.

A lot is on the line. The health of the homeowner and their family, and the protection of a big dollar investment they want to make.

As a waterproofer, you have an advantage over other contractors. You know what keeps basements dry and healthy. You know about the threat of moisture and mold. In this article, I’ll outline some important things to consider when fixing a wet basement and getting it properly prepared for finishing.

Take A Closer Look

Start off with a thorough exterior inspection. Move down to the basement and conduct a visual inspection. Is there white efflorescence on the walls, or cracks, dry rot, peeling paint, or a musty smell? These are serious conditions which will need to be addressed before a basement is finished.

Components

Let’s discuss the individual components of a drier, cleaner, healthy, more energy efficient basement.

Waterproofing: Is there an existing waterproofing system? Is it functioning properly? Is it possible that the system is clogged with silt? This is a common occurrence with older perforated drain tile and clay tile systems. Depending on the level of “peace of mind” desired, it may make sense to replace the existing system with a more up-to-date system to help ensure that no water seepage will occur once the basement is finished.

Sump Pumps: The sump pump is the heart of a waterproofing system. If the heart doesn’t work, nothing else will. I urge all installers to use a sump pump with a switch which will not get caught on debris or on the side of the sump pump liner.

Included in the waterproofing systems should be a high water alarm, which will alert the homeowners if the water level gets too high in the sump pump pit. In addition to the alarm, a high quality battery back-up sump pump should be installed.

Mold: Remember, the number one enemy of a healthy finished basement is moisture. Moisture fuels rot and what I like to call “the dreaded four letter word,” M-O-L-D. Mold can cause health problems, destroy wooden structural members, and make a home unsellable. It often isn’t covered by the homeowner’s insurance policy. By properly drying (and keeping the basement dry) the risks of mold can be greatly reduced.

If any area of the basement is suspect, a proper mold test must be performed. Simply guessing that a weird looking spot is or isn’t mold doesn’t cut it in today’s litigious society. Get a sample and promptly send it to an accredited lab. You’ll be happy you did.

If mold remediation is needed, be sure the person who is cleaning the mold is qualified to do so. An unqualified tech can easily make the situation worse.

Foundation Concerns: Inspect the basement walls. Any structural issues need to be remedied before the space is finished. If left unaddressed; these problems will often get worse with time. Since they will be covered once the walls are finished, the homeowner may not know there is a problem until the wall reaches a catastrophic condition.

Examine the walls. Are they bowed out in the middle? Check the corners for cracks. How far are they bowed? If less than two inches, then a carbon fiber repair might be best. Carbon fiber is very thin, and easily hides behind wall systems.

If the bow extends past two inches at the maximum point, then a more traditional repair, like steel I-Beams, will be necessary.

Dehumidifiers: I recommend an energy efficient, professional-grade dehumidifier with micron filtration for basement and crawl space projects. Ensure the unit has enough “reach” to maintain the air in the entire basement.

Insulation: As much as 20% to 40% of the air infiltration in a home comes from around the rim joist. The solution to this problem is spray foam insulation. Unlike fiberglass insulation, closed cell spray foam insulation is an air barrier as well as a thermal barrier, keeping unconditioned outside air outside where it belongs. This lowers the load on the HVAC system. Why not offer your clients the immediate cost savings on HVAC expenses this provides?

Modern Basement Windows: Basement windows should let in light, but not drafts, bugs or vines! Windows should not rust or rot and should seal tightly, keeping unconditioned outside air out.

Crawl Spaces: If there is a crawl space near the basement, it could allow foul odors, moisture, and mold to travel into the basement.

Conclusion

If you are finishing an unfinished space in the basement, be sure to use water and mold resistant systems. Even if you have taken all of the necessary precautions I have outlined in this article, accidents, such as plumbing leaks, can still occur.

A basement flood usually only affects the lower portion of the finishing system. If caught quickly enough, the damaged portion can be removed, mold treatment applied, and the damaged section replaced.

Do your customer a favor and become the expert. Recommend the right repairs, install them right and help them have a drier, cleaner, healthier, more energy efficient home. This is additional work that as a waterproofing contractor you can do now.

Ron Greenbaum is “The Basement Doctor.” He has spent the last 22 years building a reputation of expertise and quality in central Ohio, and has recently expanded his service area to Maryland, Washington D.C., and Virginia.

Basement Tips for Contractors:

Know Your Staff: Who is in charge of the job site? Who do you have in your customer’s home? Are they dependable, friendly and qualified? The customer will remember the installation crew long after the sales person has left.

Keep The Homeowner Updated: The foreman should give the homeowner regular updates regarding the progress of the job. Simple calls, notes or texts go a long way to alleviating worry and fear. The salesperson should also visit the jobsite and customer.

Keep Everything Positive: The crew should work well together. Updates should focus on the progress; the nitty gritty problems are not what the homeowner wants to hear. They hired you so they don’t have to deal with it themselves.

It All Starts At The Top: As the owner or manager, it’s up to you to model the right behaviors for your staff. Do you embrace your customers? Do your employees feel it’s ok to reach for the stars, or are they too busy covering their butts? Do you offer them a career, or just a paycheck? The right leadership will create an “all-in” culture and will ensure that your business is as important to your employee’s as it is to you.

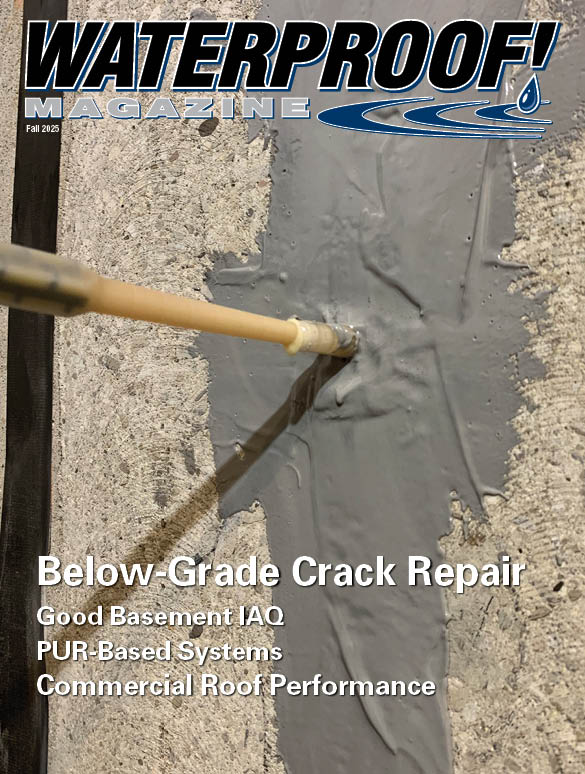

Fall 2025 Back Issue

Price range: $4.95 through $5.95

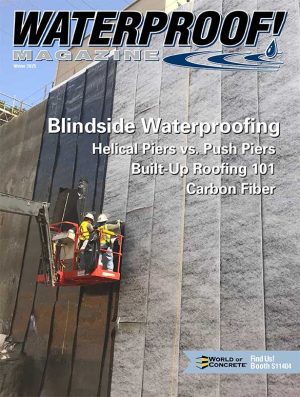

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

Restoration vs. Replacement: Maximizing Commercial Roof Performance

Below-Grade Crack Repair Solutions

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

Case Study: New York State Capitol Building

Description

Description

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

By Tom Stuewe, Senior Product Manager, Siplast

In today’s fast-paced commercial construction landscape, polyurea and polyurethane-based deck coating systems have become indispensable for their exceptional combination of durability, flexibility, and performance.

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

By Vanessa Salvia

Even if you don’t spend a lot of time in your basement, controlling the humidity and filtering that air before it moves to the upper levels of the home will improve your comfort and indoor air quality in the rest of the house.

Restoration vs. Replacement: Maximizing Commercial Roof Performance

By Vanessa Salvia

Commercial roofing presents challenges that set it apart from residential applications, such as being expansive surfaces that are almost flat. Proper maintenance programs can extend roof life well beyond design specifications and prevent the majority of warranty claims.

Below-Grade Crack Repair Solutions

By Vanessa Salvia

Modern techniques and materials are revolutionizing how contractors approach structural crack repair in basements, combining traditional injection methods with innovative carbon fiber reinforcement systems.

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

By Errol Bull, Technical Services Manager at Momentive Performance Materials

How do you know if waterproofing solutions will stand the test of time? One study, started in 1983, seeks to answer that question.

Case Study: New York State Capitol Building

A centerpiece in the heart of Albany, the New York State Capitol Building’s central courtyard required updates to its roofing and cladding.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |