Wastewater treatment plants are notoriously difficult to waterproof. But an innovative waterproofing technology may offer an elegant solution.

Sewage treatment, or domestic wastewater treatment, is the process of removing contaminants from wastewater and household sewage. It includes physical, chemical, and biological processes to remove physical, chemical and biological contaminants. Its objective is to convert the waste stream into an environmentally safe product.

The holding tanks, treatment chambers, and channels that connect them are nearly always made of cast concrete. The sheer scale of these projects is often daunting. (A single repair job in Miami involved remediation of 52,000 sq. ft. Large plants serving major cities sometimes run to the hundreds of thousands of square feet.)

Beyond size, though, there are other unique issues. Jim Caruth, technical services manager at Xypex explains, “Typically, the walls are quite tall, and they’re restrained [connected] only on the bottom. So shrinkage ore restraint cracks are often there from the very beginning. There are also lots of joints that need to be addressed. And once the facility is placed into service, that concrete is constantly immersed, and usually under significant hydrostatic pressure.”

Some of the tanks are exposed to erosion, as the contents are agitated regularly. Others are exposed to corrosive hydrogen sulfide gas above the waterline.

Caruth says crystalline waterproofing technology can address every one of these challenges, and provides a cost-effective, long-term solution for both new construction and remediation of existing plants.

“There are no real secrets here,” he says. “The problems affecting wastewater treatment plants are fairly simple. The product selected needs to supply both waterproofing and chemical protection.”

The Process

Raw waste arrives at the area of the plant known as the headworks. The grit chamber of the headworks area is where incoming material is screened and the large solids dewatered and sent to the landfill. Liquid wastes with smaller bits of debris are sent to the settling chambers for further treatment. Concrete in the headworks is subjected to turbulence, erosion, and sometimes large amounts of hydrogen sulfide gas.

Caruth says, “Because of all that turbulence and solid material still in the waste stream, the headworks tend to see a lot of erosive effects on the concrete. Membranes and coatings tend to get worn off. Optimally, designers want a waterproofing solution that is integral to the concrete and doesn’t depend on the integrity of a surface coating.”

The waste stream then moves on to a series of tanks: flocculation chambers to encourage the solids to coallese, settling chambers to allow solids to separate, and digestion chambers to process organic material. Sometimes it’s processed a second or third time before being disinfected and disposed of. The end product is clean water.

The Solution

Obviously, all of the water-holding structures need to be waterproofed in some way. In the past, engineers have specified cementitious coatings, epoxies, urethanes or polyureas. These are all physical barrier systems and offer a high level of chemical resistance. However, Caruth points out that all these coatings are expensive, require extensive surface preparation, and have a limited lifespan requiring future maintenance.

In contrast, crystalline waterproofing makes the concrete itself impermeable, penetrating deep into the matrix when applied as a coating or being fully dispersed through the concrete when used as an admixture. It even has self-healing characteristics, capable of sealing hairlinecracks. While new concrete crack healing technologies have been much in the media recently, the crack healing properties of crystalline waterproofing has been well documented for decades.

Concrete is composed of sand, gravel, water, and cement. When the cement combines with water, it undergoes a chemical reaction which causes the mixture to harden into a solid, rock-like mass. Most of the water added to concrete, though, is “water of convenience” added not for hydration, but to improve the workability of the wet concrete. When that water of convenience evaporates, it leaves behind pores, voids and capillary paths that make the concrete both porous and permeable.

Crystalline waterproofing seals these pathways. Basically, chemicals in the waterproofing react with water and chemicals already in the concrete to form insoluble crystals that grow into these voids and cracks, sealing them off permanently. These chemicals can lie dormant for years in the concrete, but will activate if water is reintroduced, such as through a new crack. Because of this, it cannot be punctured,damaged or wear out like a liner or surface coating, and is not affected by humidity, light, or many of the chemicals found in the waste water treatment process.

Xypex’s crystalline waterproofing is a dry powder composed of Portland cement, very fine treated silica sand, and proprietary chemicals. It is produced as a coating material, admixture and dry shake. The dry shake is suitable for newly poured, concrete slabs. The slurry coat is suitable for existing concrete or new construction, joints, and remediation work. Special products and procedures are available for treating active leaks, patching and repair. The coatings can be applied by brush or spray equipment. There are no VOCs, so they are suitable for application even in confined space.

For new construction, crystalline admixtures are usually the best choice; it minimizes installation costs, shortens the construction schedule, and ensures the concrete is thoroughly treated. Typical dosage rates for wastewater plants are 2% to 3% ratio by weight of Portland cement. (Headworks, because of the potential for aggressive chemicals, are typically dosed at the 3% rate.)

Summary

Caruth says, “These are typically very big projects with a lot of concrete. That increases the chances that somewhere in the job, there will be a ‘bad load.’ With big jobs, mistakes sometimes get made and things can go wrong resulting in concrete getting placed even after the maximum placement time has been exceeded or an area is not consolidated as well as it could be.. Crystalline waterproofing, such as Xypex, can help ensure that even these instances of placed concrete are waterproof.”

Despite the challenges presented

by wastewater treatment plants, it’s possible to keep them waterproof using integral crystalline products. Thousands of projects worldwide show they’re a proven, effective solution. They offer cost effective, permanent, integral waterproofing for both new and existing facilities, with most of the advantages of the barrier systems and none of the drawbacks.

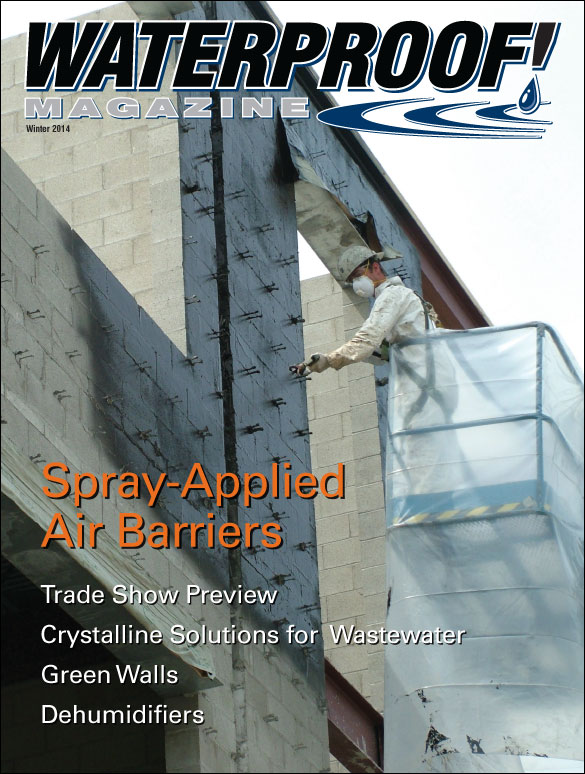

Winter 2014 Back Issue

$4.95

Selecting a Spray-Applied Air Barrier

The Importance of Dehumidifiers

Crystalline Solutions for Wastewater Plants

A Different Direction: Green Walls

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Selecting a Spray-Applied Air Barrier

by Colin Szewaga

Air barriers are becoming more common because they reduce energy use and many codes now require them. Fluid-applied membranes are especially popular because of their continuity, strength, and airtightness.

The Importance of Dehumidifiers

Dehumidifiers are often a critical component of a waterproofing system. But determining their size, placement and features is an essential part of making sure the units perform as intended.

Crystalline Solutions for Wastewater Plants

Waterproofing and sealing wastewater treatment facilities are difficult because of the constant immersion, extreme head pressure, and sometimes caustic chemicals.

A Different Direction: Green Walls

No longer satisfied with green roofs, designers are now developing vertical gardens and green walls, which require a new approach to waterproofing.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|