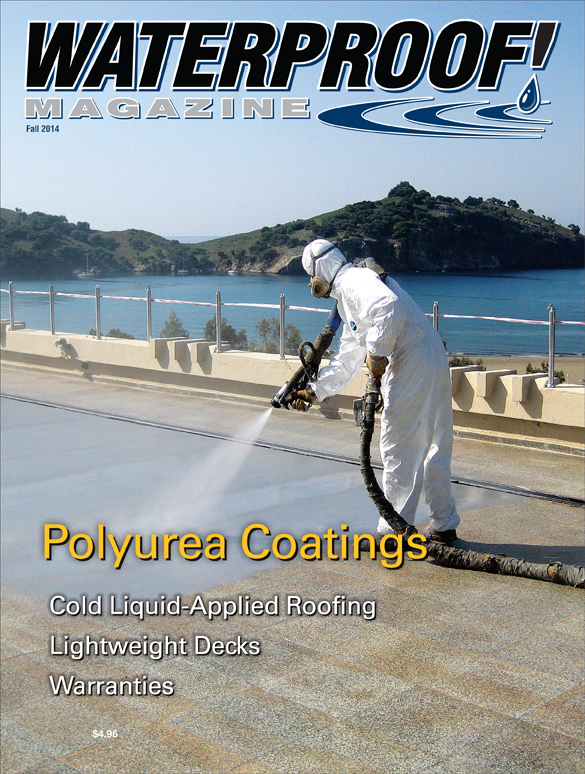

Polyurea is an extremely versatile compound, and has been used successfully for waterproofing tanks, parking garages, reservoirs, tunnels, and as a joint filler/caulk.

The list of materials used as waterproof coatings through the ages is lengthy. For centuries, asphalt-based products such as pitch and tar were the only choice. In the 20th Century, a range of other options developed, including paint, epoxy, fiberglass and vinyl esters.

The latest coating technology is polyurea. Developed in the late 1980s for the automotive industry, this material is now used in a wide array of applications. Use of this material as industrial waterproofing has skyrocketed in popularity in the past decade due to its fast-curing, corrosion- and abrasion-resistant characteristics

Andy Phelan, director of business development and training at Rhino Linings Corporation, explains, “Polyurea was invented in the early 1980s when a less moisture-sensitive form of polyurethane was desired. By replacing the hydroxyl group in the urethane with an amine group, a product we now call polyurea was formed. It has significantly less sensitivity to moisture than other urethane-based coatings.”

Of the two most common types of polyureas, aromatic polyureas are by far the most common. Phelan calls them “the workhorse of the industry offering a wide variety of physical characteristics for various uses.” In fact, about the only characteristic these coatings do not provide is UV stability.

A second formulation, aliphatic polyureas, use a different chemistry to provide UV stability. This added benefit comes at a price as aliphatic polyureas are typically twice the price of aromatic polyureas.

Benefits

One reason polyurea coatings are exploding in popularity is the wide variety of positive attributes they exhibit.

The industry website, polyurea.com, opens with a bold statement. “Virtually no other coating can compare to polyurea when it comes to attainable physical properties,” it reads. “Polyureas can be formulated to achieve a tremendous range of properties from high elongation to superior tensile strength to hard or soft, all based on how the materials is formulated and correctly applied.”

It adheres tenaciously to a variety of different substrates (concrete, metals, wood and more) without primers and in a wide range of temperature and humidity environments.

Perhaps its greatest advantage is that it sets up extremely quickly, allowing the applicator to build up a finished thickness in a single pass. This allows the owner to put the facility back in service many times faster than traditional coatings, saving days or even weeks of revenue lost to down-time.

Phelan says, “Thicknesses can range from 20 mils to 500 mils in one application. Cure times range from instantaneous to two minutes allowing for quick return to service.”

As a fast curing, thick film coating, polyurea is a logical solution when seamless, durable membranes are needed for waterproofing. Additional characteristics such as slip-resistant additives and surface textures can also be incorporated. It can be colored, and is even available in a potable-water-approved formulation.

With such a wide range of performance characteristics, the range of suitable applications is also broad. Tank linings, secondary containment and bridge coatings are some of the most popular uses, but the application possibilities are endless.

Polyurea can be used to waterproof both the joints and the surfaces of many concrete structures, such as this reservoir near Huntsville, Alabama.

The technology has been used successfully on pedestrian decks and parking garages, reservoirs, tunnels, water tanks, slurry pits, and flooring. It can also be used as a joint filler/caulk.

Polyurea was originally used as a truck bed liner to form a permanent watertight layer. The same durable and abrasive-resistant characteristics that make it perfect for lining pickup beds and dump trucks make it attractive for difficult waterproofing projects.

The tanks at wastewater treatment plants, for example, are exposed to turbulence, erosion, and large amounts of hydrogen sulfide gas as the contents are screened, mixed, and dewatered.

Polyurea coatings can supply the abrasion, chemical, and impact resistance needed, and restore the plant to operating condition faster than many other competing systems.

For bridges and other applications exposed to vibrations and movement, the inherent flexibility of polyurea is an added benefit over thinner, less flexible coatings like epoxy.

Drawbacks

Polyurea does have a few drawbacks. Phelan notes that the equipment required to apply polyurea coatings can be expensive. It can range from $15,000 to $50,000 or more. Fully equipped mobile platforms can cost more than $100,000.

The material also costs more than some alternatives. Phelan says initial costs are higher than epoxies, but since polyurea coatings can last three to five times longer, it becomes quite cost effective over the life of the coating.

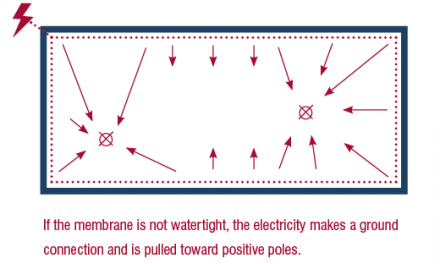

As with any waterproofing material, it can fail if applied improperly. Surface preparation —usually sandblasting or priming—is crucial for a successful application. Most failed polyurea coating projects have little to do with the polyurea itself, but rather, inadequate or poorly implemented surface preparation.

About 54,000 sq. ft. of polyurea waterproofing was applied to this potable water tank at the U.S. Army’s Redstone Arsenal.

Installation

Most polyureas used for waterproofing are spray-applied with plural component spray equipment.

It’s typically shipped as a two-part system, with the amine resin blend and isocyanate material supplied in 55-gallon drum sets. Once in use on the jobsite, they are transferred from 55-gallon drums to separate tanks in the spray equipment where they are heated to the appropriate temperature (140°F-160°F). The machine then delivers the isocyanate and polyol resin through heated hoses to the spray gun in a precise ratio (usually 1:1).

Polyurea has a set time that is measured in seconds, so it’s crucial that the chemicals don’t mix until the instant before they leave the gun. Otherwise, the material will set up and harden inside the gun.

Several manufacturers sell mobile spray rigs that include all of the tools and equipment needed, mounted on either a trailer or truck bed.

CASE STUDY: McLeod Dam

Belleville, Ontario, Canada is a city of 50,000 located the north shore of Lake Ontario, straddling the major highway connecting Toronto to Ottowa and Montreal.

This critical highway and the surrounding buildings were at risk of flooding because the waterproofing membrane on a nearby dam had failed and significant amounts of water were saturating the dam and surrounding soil.

The McLeod dam and floodwall was built in 1978 to protect downtown Belleville from ice-related flooding. However, the original PVC liner had decayed to the point that water was seeping into the basement of nearby businesses and the hydropower turbines were affected.

Quinte Conservation, which manages the property, needed to restore the waterproofing membrane. But because the floodwall ran under the municipal road, removal or repair of the PVC liner was not feasible. The repair’s appearance was also a concern. They wanted to preserve the rocky slopes of the reservoir and overall natural beauty of the area.

Quinte Conservation chose to use geotextile fabric and a spray-applied, fast-set polyurea. Rhino Industrial Linings Extreme 11-55 got the nod. This product is a pure polyurea formulated for extreme outdoor conditions where water, humidity or low temperatures may exist. It creates a seamless, monolithic barrier.

In 2011, the project got underway. After the dam’s water level was lowered, loose debris and large rocks were removed from the site. A concrete curb was installed at the base of the embankment, which served to secure the lower end of the geotextile fabric. A trench keyway along the top of the reservoir holds the upper edge of the liner in place.

The sheets of geotextile were then rolled out, seamed together, attached at the top and bottom keyways and sprayed with Rhino’s product to a thickness of 80 -100 mils (2 -2.5 mm) in a single pass.. Finally, gravel and larger stones were layered above the polyurea/geotextile fabric to protect it from UV degradation and imitate the look of a river bed. The water level was raised gradually to reach its normal level, and the reservoir was put back into operation.

The $700,000 project took about four weeks to complete.

Three years after the project, Quinte Conservation engineers are still very happy with the results. “It is performing to expectations and was an excellent way to remediate our embankment,” said Bryon Keene, Quinte Conservation’s water resources manager. “The old liner had failed and although this option was more expensive, we felt it was more durable and would withstand the harsh environment. We placed riprap directly over the surface of the liner with heavy machinery and it easily withstood the placement.”

With routine maintenance, Quinte Conservation expects to get at least 40 years of service life from polyurea lining.

Fall 2014 Back Issue

$4.95

Apples To Apples – Comparing Waterproofing Warranties

Polyurea Coatings: The Basics

Cold Liquid-Applied Roofing By Kelly Franklin

Moisture And Lightweight Decks

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Apples To Apples – Comparing Waterproofing Warranties

Manufacturer warranties can be confusing, and often focus on the length of coverage instead of the terms. Here’s what a good warranty should cover as well as the limits of liability.

Polyurea Coatings: The Basics

Developed in the 1990s for the automotive industry, this technology has skyrocketed in popularity due to its fast-curing, corrosion- and abrasion-resistant characteristics.

Cold Liquid-Applied Roofing By Kelly Franklin

New technology allows built-up roofing to be applied without hot tar kettles, open flames, or noxious odors. A few are self-flashing and require no reinforcing mesh.

Moisture And Lightweight Decks

An increasing number of residential projects involve walkable roof decks. Careful design and detailing are crucial to ensure that they remain waterproof.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|

Very Useful. This article dispelled a lot of myths regarding polyurea

Hi would like more info on waterproofing membrane for foundation