The construction industry has primarily utilized passive waterproofing membranes for the past 50 years.

In recent years, though, the increasing popularity of shotcrete in the construction of below-grade foundations and subsequent water ingress failures have led to new developments and commercialization of active membranes.

These new active waterproofing membranes introduce measures of redundancy by combining materials to create hybrid membrane products.

Hybrid below-grade water-proofing membranes combine active polymer barrier technology with conventional passive-bonded product technology in an effort to counter failure trends. By incorporating multiple barrier materials in a single waterproofing membrane, the new active polymer hybrid membranes compensate for the shortcomings of traditional materials in relation to workmanship and dependence on perfect installation to prevent failure. By recognizing modes of failure in traditional membranes, new active products are being engineered to prevent failure by combining different material layers that increase the failure modes that must occur at a specific location for water ingress to occur. The common trend among all emerging active waterproofing systems is a recognized need to adapt to current construction techniques and perform at a higher level to prevent water ingress.

Active polymer waterproofing can withstand high hydrostatic conditions and work in both intermittent and continuous groundwater conditions. Most conventional passive products rely on an adhered physical material barrier resistance to water. Passive technologies are usually reliant on chemicals in terms of adhesion or inherently water resistant technologies such as bituminous and thermoplastics. Active polymer waterproofing is not only a physical material barrier resistant to water but can also self-heal, self-seal with water; thus using the problem, water ingress, as part of the solution to provide a dry structure.

Multi-layer vs. Single Material Type Systems

The Environmental Protection Agency (EPA) adopted a policy for municipal and hazardous waste landfills that requires the use of a multi-component lining system that utilizes both a passive polymeric membrane, as well as, a “active” clay sealing layer. The basic concept behind this type of design is to use a redundant system in the event one layer is breached and the second layer of material functions by means of a different failure mechanism than that of the other. In landfills, research showed improved performance of the entire system when two different materials were used together providing a synergistic effect for hydraulic barrier performance. The active polymer hybrid waterproofing membranes conform to EPA’s redundant barrier concept by being a multi-component, multi-failure mechanism barrier system.

The Trend Toward Active Membrane Hybridization

All waterproofing systems work to some extent or they would not be commercially accepted technologies. However, it is important to recognize that water ingress is usually never the result of the material itself. Poor workmanship, improper application, and third-party damage after installation are ultimately the undoing of even the best waterproofing technologies. Products that need to be mixed onsite, products that are labor intensive to install, and lack of trade coordination can create problems on most jobsites.

As below-grade waterproofing failures are difficult and costly to address, the issue has motivated manufacturers to develop active waterproofing membrane systems. The developed active systems are hybrid products that introduce reliability by combining different materials and installation methods.”

The advantage of incorporating two layers of waterproofing, regardless of integration into a single membrane, is immediately apparent: two layers of protection are better than one. A combination of waterproofing materials allows the composite membrane to leverage the capabilities of each layer while enhancing the performance of both through redundancy and continuous, uniform placement.

Below-grade construction sites are frequently not conducive to the installation of waterproofing membranes. These sites collect water, mud, and debris and are staging areas for materials and equipment. Many trades will be working on or in close proximity to the membrane. Construction activities such as rebar, mechanical penetrations, and concrete placement can all cause damage to the installed membrane. In consideration of the challenging work environment into which the waterproofing membrane is installed, it is understandable why many are damaged after being placed, and why a hybrid membrane with an active, self-sealing layer is the preferred choice for applications where adverse installation conditions exist.

Active Polymer Hybrid Options

The trend towards combining products to develop an active polymer hybrid membrane originated in bentonite membranes. Initial active dual membranes consisted of a layer of sodium bentonite combined with a polymeric liner or durable polymeric geotextile composite. One of these hybrids included the compounding of the bentonite with butyl-rubber to form the active, swelling layer. Since this early product hybridization, manufacturers have further developed and commercialized membranes with hydrophilic polymer technologies or installation methods such as thermoplastic welding of seams.

Available in two formulations based on groundwater salinity, Ultraseal active polymer waterproofing has been used successfully on many below-grade construction projects, throughout the United States and Canada.

Active Polymer Core Technology

The first active polymer hybrid membrane system, Ultraseal, was introduced in 2002 by Cetco. Today, the Ultraseal product line consists of two distinct technology options: one for low to moderate saline groundwater site conditions (Ultraseal BT and Ultraseal SP) and the second for high saline groundwater site conditions – Ultraseal XP. The active, polymer layer of all three products is laminated to a passive polymeric geomembrane liner. Each of these products have a proven track record in difficult conditions such as hydrostatic pressure, saline groundwater conditions, property line, shotcrete, and tunnel applications.

The membrane design and installation techniques provide for the passive polymeric liner component to always face outward toward the positive groundwater pressure which allows the active polymer core layer to be in direct contact with the exterior concrete surface to activate and prohibit lateral water migration.

Coreflex combines an Active Polymer core with a highly durable PVC membrane. This allows all seams to be heat-welded to form a seamless watertight barrier. Active polymer technology will mechanically bond to poured concrete, and when activated, enhances the seam integrity of the CoreFlex.

Ultraseal membranes can be fully adhered to the exterior surface of backfilled cast-in-place concrete walls using Hydrofix. Hydrofix is a cold-applied, polyether-based waterproofing membrane that functions as an adhesive to secure the Ultraseal membrane; plus provide waterproofing barrier redundancy. Under slab, the geotextile facing of both Ultraseal membranes will form a strong mechanical bond to the bottom of the slab securing the membrane in place. To complete the backfilled foundation wall installation, a 75 mm (3”) wide Seamtape is applied continuous and centered over each membrane overlap seam.

Ultraseal active polymer waterproofing has been used successfully on many below-grade construction projects, including high hydrostatic below-grade conditions with both backfilled and shoring retention walls, throughout the United States and Canada.

The first active polymer hybrid membrane system was introduced in 2002, and has a proven track record in difficult conditions such as hydrostatic pressure, saline groundwater property line, shotcrete, and tunnel applications.

Active Polymers and PVC

Cetco offers another product with Active Polymer Core Technology. Called CoreFlex, it also conforms to the EPA redundant barrier concept by being a multi-component barrier system that utilizes a welded reinforced thermoplastic membrane with an integrally bonded Active Polymer Core (APC) layer.

CoreFlex 60 is a composite waterproofing membrane consisting of a 1.5 mm (60 mil) reinforced plasticized polyvinyl chloride (PVC-P) thermoplastic membrane combined with an integral active polymer core layer supplied in uniform rolls of 1.37 m (54”) wide by 15.2m (50 feet). During installation, the overlap edges of the PVC-P membrane are fused together by hot air welding to form a seamless watertight thermoplastic membrane barrier. The active polymer self-sealing layer provides redundancy waterproofing performance, mechanical bonding to poured concrete, and protection course functionality during underslab and property line wall applications. Furthermore, the swelling and sealing of the APC core enhances the seam integrity of the CoreFlex by means of a redundancy layer at each overlap. Where these two material layers are overlapped a minimum of 100 mm (4”) to work synergistically to provide superior waterproofing protection.

The CoreFlex 60 PVC-P thermoplastic membrane component is strengthened with a knit polyester reinforcement fabric and is produced with a high molecular weight (>10,000 g/mol) Ethylene Interpolymer Alloy (EIA) at a high concentration of the total polymer content. The EIA functions as the plasticizer and is the foundation of the thermoplastic chemistry to provide a high resistance to chemicals and long-term physical properties. The membrane incorporates antioxidants, fungicides, and fire retardants. The entire membrane composite self-extinguishes after an open flame is held against the membrane for 10 seconds; thus providing a high level of safety during installation.

CoreFlex 60 has been successfully tested to resist 70m (231-feet) of hydrostatic head pressure per ASTM D5385 (mod) and 1,741-feet (754 psi) of hydrostatic pressure per ASTM D751. The durable membrane composite has a low water vapor transmission of 0.1 perms per ASTM E96 and when concrete is poured against the APC layer provides a peel strength of 10-lbs/in per ASTM D903 (mod). Additionally, CoreFlex 60 was issued general approval as a methane barrier by the City of Los Angeles after passing their stringent testing program criteria.

The CoreFlex system can incorporate expansion joints glands heat welded directly to the PVC-P membrane component to provide a fused thermoplastic seal at movement joints and expansion joints. Also the CoreFlex system can incorporate both hydrophilic strip and/or injection hose concrete joint waterstops, and drainage sheet composites.

The CoreFlex waterproofing system has been used successfully on many below-grade construction projects, including high hydrostatic below-grade conditions (both backfilled and shoring retention walls), plaza deck, and greenroof applications, throughout the United States and Canada. In addition CoreFlex has been used successfully as a methane barrier on projects in the United States.

Conclusion

Active polymer based hybrid products have been successfully installed in the United States and Canada for nearly 15 years. Waterproofing membrane selection depends on the owner’s tolerance for risk of water ingress, the construction method and sequence, and project site factors such as the potential for hydrostatic groundwater pressure. The ability of the membrane to survive the construction process, or its construction survivability, is a vitally important aspect of any product evaluation or comparison. Active waterproofing membranes with their dual barrier components are certainly an advantage over other passive membranes whose in-situ performance depends on the integrity of a single barrier component applied correctly that could be easily damaged by other activities on site.

Stacy Byrd has more than 24 years of product management and technical sales experience in the waterproofing industry. He is currently national products manager at Cetco, where he oversees commercial waterproofing and greenroof systems as well as prefabricated drainage and concrete joint waterstops.

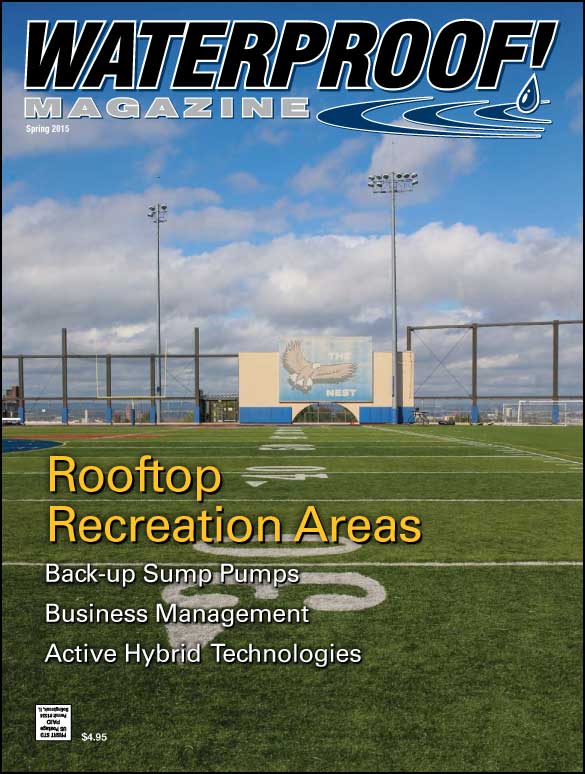

Spring 2015 Back Issue

$4.95

Active Hybrid Waterproofing Technologies

Back-up Sump Pump Systems

Rooftop Recreation Areas

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Active Hybrid Waterproofing Technologies

By Stacy Byrd

This new non-curing, self-sealing technology makes it easier than ever to confidently waterproof difficult areas. It’s already been used on several landmark products.

Back-up Sump Pump Systems

By Blake Jeffery

Every home with a sump pump should have a reliable backup sump pump system to protect from problems such as power outages, switch malfunctions, and clogs.

Rooftop Recreation Areas

By Michael Popke

Pressed for space, campuses on both coasts have found room to expand their athletic fields by building stadiums on top of existing buildings. Obviously, waterproofing was a major concern.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|