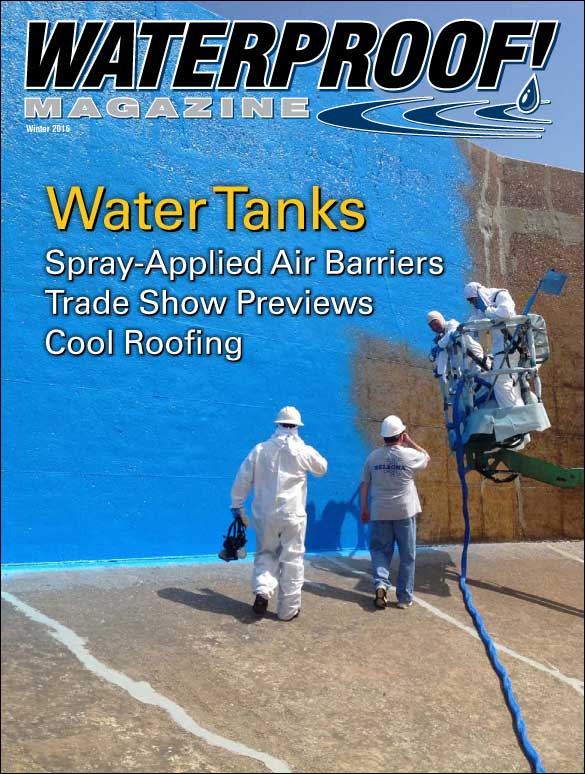

Epoxies, acrylics, polyurethanes and cementitious slurries (shown here) are all used as tank coatings.

Most Americans take drinking water for granted. We expect clear, contaminant-free water to be instantly available at the turn of a faucet.

Behind this modern miracle lies a network of water tanks and water treatment plants that supply 50 billion gallons of water a day. However, much of this infrastructure is nearing the end of its designed service life, and needs maintenance and waterproofing. Additionally, new tanks and treatment plants are being built to serve growing populations.

An increasing number of waterproofing contractors are finding that protecting and sealing these tanks that treat and store America’s drinking water is a profitable niche. Nearly all of these tanks are either steel or concrete, and in many respects, the work is similar to sealing any other steel or concrete surface. However, storage tank coatings must be safe for potable water, and treatment tanks are exposed to abrasion, wet/dry and freeze/thaw cycling. Additionally, the limited access and confined spaces typical of this work often add a considerable level of difficulty.

New technology developed over the past years means environmentally-friendly coating systems now offer protection similar to the solvent-based products of the past. In many cases, they’re also easier to apply, more economical, and effective as well.

The First Steps

The first step to remediation is determining why the tank is deteriorating in the first place. This is usually beyond the scope of the repair contractor, and is done by consulting engineers or concrete testing firms. The root cause could be chemical attack, abrasion, freeze/thaw cycling, wet/dry cycling or something more basic, such as foundation settlement.

One common problem with concrete tanks is that hairline cracks develop and allow water to penetrate to the reinforcing steel and create rust. This chemical reaction expands the volume of the rebar significantly and with tremendous power, enough to crack the concrete further. This of course, creates a self-perpetuating cycle that must be addressed by the waterproofer.

Epoxies are among the most popular coatings due to their outstanding adhesion and abrasion resistance.

Penetrating corrosion inhibitors have been developed to slow down this process. Some are powder-based and can be added to new concrete as a preventative measure. Others are liquid, and are sprayed onto the surface of the concrete. These products will actually wick through the same microscopic channels as the water to the reinforcing steel and form a protective layer. But in severe cases, the concrete must be removed, the steel blasted clean, and then the tank rebuilt.

Concrete and steel can be protected from abrasion, wet/dry cycles, and chemicals by installing a membrane between the water and the structural surface of the tank.

Polymer-modified cementitious coatings are one popular choice for concrete potable water tanks. Epoxy coatings work well for both steel and concrete, as do polyureas and polyurethanes. Metal structures require additional protection. The exteriors are usually painted with a direct-to-metal acrylic coating, which are economical, durable, UV-resistant and offer long-term flexibility. Two-part epoxy-based coatings are also popular, since they adhere well to a wide range of old coatings with minimal surface preparation. Metal tanks also require cathodic protection, which is beyond the scope of this article.

Epoxies

Two-part epoxy systems are a popular coating for tank interiors. They have excellent chemical resistance and are simple to apply. However, they do require diligent surface preparation, and the surface must be completely dry.

Waterborne epoxies combine the convenience of a water-based coating with the performance of conventional epoxy. These coatings offer outstanding adhesion and corrosion protection. They are highly acid, alkali and moisture resistant, and can withstand heavy abrasion. Dallas Finch, formerly director of Sherwin-Williams Industrial Coatings and Marine Division, says high solids epoxy mastics are specified for the overwhelming majority of potable water storage tank interiors. “There are few coating types that can meet both the toxicological and extraction test requirements of ANSI/NSF Standard 61 and the long-term corrosion protection needs of potable water storage tanks,” he says. “Among the two most effective, only high solids epoxies have been formulated to acceptable VOC emission levels.”

One drawback to epoxy-based coatings is that they cannot be applied to wet concrete, such as tanks that have been recently drained to permit work to be done. Greg Illig, a concrete tank coating expert, says, “If the moisture content is greater than four percent, the moisture in the pores of the concrete can prevent the epoxy from bonding well to the concrete. Likewise, it is not advisable to apply an epoxy coating on new concrete until it is at least 28 days old, so that the concrete has a chance to hydrate and the moisture content has a chance to drop.”

Sometimes, construction and repair schedules do not allow enough time for this to occur. In these cases, an epoxy-cement mortar (water-based epoxy resin+cement) can be applied as a primer. Illig says, “Applied as a leveling mortar, this thin epoxy-cement mortar layer will act as a temporary moisture barrier on the surface of the concrete long enough to allow the epoxy coating to achieve an adequate bond. In addition to solving the moisture problem, the cement-epoxy mortar layer also fills in bugholes, honeycombs and pores on the surface of the concrete.”

Polyureas/Urethanes

Polyurethanes first gained pop-ularity as a tank coating in the 1970s. They’re extremely versatile, and depending on the formulation can be hard and rigid or soft and flexible. They withstand abrasion and impact, and meet most VOC requirements.

Within the past few years, polyurea coatings have gained significant market share because of their speed, versatility, and fast dry times. Advanced polyurea coatings and liners deliver a strong, flexible waterproofing that bridges large cracks and can elongate up to 400% without cracking. The spray-applied waterproof coating creates a seamless, waterproof, protective liner that stops leaks and strengthens the integrity of the entire storage structure. It is designed to withstand decades of freeze-thaw cycling and wide variations of temperature and humidity.

“VersaFlex polyurea sets up in seconds and can be put back into service as fast as an hour. It can take days for epoxy to cure enough to do the same. The time saved can provide tremendous savings to a facility,” says Brian Burgess, vice president of Contracting & Materials (C&M), a Decatur, Alabama-based specialty industrial coatings contractor. His company was chosen to rehabilitate a World War Two-era water tank with cracks as wide as 1/8″.

Polyurethanes are flexible, fast-drying, and tough.

“The tank was losing a significant amount of treated drinking water, which is expensive,” Burgess says. They chose VersaFlex’s AquaVers 405, which is ANSI/NSF 61.5 approved and meets potable water requirements.

The first step was to drain the tank and pressure wash the walls. All cracks over 1/8″ wide were repaired with a concrete repair grout, then primed, and finally coated 80-100 mils of the polyurea coating. The product was issued a 75-year life span by Bechtel Engineering on the “Big Dig” Boston Tunnel Project.

Other companies also offer polyurea tank coatings. For instance, Rhino Lining’s Hi-Chem provides excellent corrosion resistance and will not deteriorate from most chemical attacks and is ideal for wastewater treatment facilities. Their Pipeliner series of products are formulated to meet the NSF/ANSI 61 potable water standard, and have excellent flexibility to resist impact damage and abrasion.

Cementitious Coatings

For concrete tanks, cementitious coatings may also be an option. Many are formulated with crystalline waterproofing technology, which gives the coating the ability to “self-heal” hairline cracks. These coatings are applied at a much thicker rate than epoxy or polyurea products; 1/4″ to 5/8″ is typical.

Tank coatings can be profitable, but the work requires careful attention to safety and confined space/limited entry practices.

W.R. Meadows Cem-Kote Flex is a polymer-modified cement membrane, which can be applied by brush or with spray equipment for larger applications. While not as flexible as polyurea, this coating does offer excellent adhesion, and can be applied to wet (or even completely water-saturated) concrete. A reinforcing fabric gives the material crack-bridging and flex characteristics.

Conclusion

Water tank construction and repair has significant potential for the waterproofing industry. According to industry sources, the U.S. municipal water and wastewater sector will need to invest $260 billion over the next 20 years to keep up with expected demand.

Finch says, “A whole new breed of protective coating systems is available for corrosion control of potable water storage tanks. These new systems include waterborne epoxies, acrylics, mastics and high-solids epoxies and urethanes. Some of these coatings are better for new tank applications, while others exhibit superior adhesion to existing finishes. The key to achieving effective corrosion control is specifying the coating system with the right properties for the site-specific tank conditions.”

Winter 2016 Back Issue

$4.95

Coatings for Water Tanks

Cool Roofing: Reflective v. Planted

Spray-Applied Air Barriers: Thick vs. Thin

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Coatings for Water Tanks

From potable water storage to wastewater treatment, these coatings will provide corrosion protection, waterproofing, and peace of mind.

Cool Roofing: Reflective v. Planted

Light-colored reflective membranes and vegetated roof systems are both described as “green” roofs. Case studies and lab reports demonstrate the environmental benefits of each type.

Spray-Applied Air Barriers: Thick vs. Thin

Fluid-applied vapor barriers are popular for their continuity, strength, and effectiveness. Thick- and thin-film barriers both claim to be effective.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|

I would like to use PVC pipe to store water on an overland vehicle. What is the best “food safe” coating to use? Epoxy, Urethane or something else?