By Meredith Cook

Crews applied 700,000 board feet of Geofoam over the St. Pete Pier concrete deck.

On July 6, 2020, the city of St. Petersburg welcomed Floridians to a revitalized 26-acre attraction—St. Pete Pier. Serving as a premier destination for residents and visitors alike, the new pier hosts amenities ranging from an open-air market to performance spaces. The largest waterfront park in the Southeast also features public art installations sprinkled throughout. Raul Quintana, city architect for St. Petersburg, told ABC Action News, “It will be better than Disneyland, because it’s free. You don’t have to pay any money to visit. Whether you have 50 cents or 50 dollars, there will be something for you to do.”

According to an article on Thrillist, the city of St. Petersburg has had a pier since the late 1800s, though the structure was merely an empty stretch of boardwalk leading to a single building. “The city then built an inverted five-story pyramid pier in the 1970s,” says Dave Hall, Insulfoam territory manager. “This closed in 2013 to start the new renovation.”

To build up the quarter-mile bridge leading to one of St. Pete Pier’s main focal points, the project architect and engineer chose Insulfoam GF19 (Geofoam) EPS19 to apply over the concrete deck. The geosynthetic material is a high-performance, lightweight fill consisting of closed-cell expanded polystyrene (EPS).

The material was selected for its weight and predictable performance, along with its ease and speed of installation. In the field, the construction team used four levels of 12-inch Insulfoam GF, which they staggered upwards. Starting with a 2-inch channel board laid over concrete, crews then placed a layer of 10-inch Insulfoam GF blocks. For the remaining levels, workers topped the 12-inch system with three additional layers of 12-inch Geofoam.

Park patrons will be supported underfoot by Geofoam, a lightweight fill consisting of closed-cell EPS.

With more than 700,000 board feet. of rigid foam, “The biggest challenge was getting materials out there a quarter-mile on this bridge,” Hall said. Fortunately, Insulfoam GF’s lightweight properties meant that, “the subcontractor could take a full semi-tractor trailer out there and offload rather than bringing truckload after truckload of material,” he continued. While the use of Geofoam required about 20 truckloads to complete the job, the project would have needed over 240 truckloads of soil to construct the same walkway.

The geosynthetic fill was also a more attractive option than soil, as a geofoam approach helped lighten the load on the substrate. As Hall summed up: “It’s basically a bridge over water, and you don’t want additional weight over water.” What’s more, unlike soil, the Insulfoam GF solution isn’t in danger of washing out, a key factor given Florida’s rain-prone environment.

Along with its minimal weight, great convenience and ability to stay in place, Geofoam doesn’t require specialized equipment for maneuverability. Instead, with fewer logistics and less machinery than traditional soil, building teams can simply put the blocks where they need it to go with their own two hands. The contractor described the process as “‘putting together a puzzle.” As well, there weren’t any radius cuts to be made,” Hall said. Instead, most of the field cuts were rectangular and easily completed with the assistance of a hotwire cutter. The result? A quicker, more efficient installation.

While the design for the reimagined St. Pete Pier was approved in 2015, the attraction wouldn’t open to the general public for five more years. As St. Petersburg Mayor Rick Kriseman put it in a June press release, “It’s been a long and winding road, but we’ve arrived at our destination: A dynamic, 26-acre waterfront playground that will serve residents and visitors for generations to come. It’s time for everyone to experience all the Pier District and St. Pete Pier has to offer.” Supported by lightweight, enduring Insulfoam GF (Geofoam) underfoot, patrons can now stroll and bike along the local landmark for years to come.

Project Statistics

LOCATION: St. Petersburg, Florida

PROJECT TEAM:Subcontractor: BrightView www.brightview.com

GENERAL CONTRACTOR: Skanska USA www.usa.skanska.com

PRODUCTS USED: Insulation System: Insulfoam GF19 (Geofoam)

AMOUNT OF PRODUCT: 3 sizes of Geofoam EPS19: 2” x 48” x 96” with channels; 10” x 48” x 96”; and 12” x 48” x 96”; Over 700,000 board feet of Insulfoam GF

Winter 2022 Back Issue

$4.95

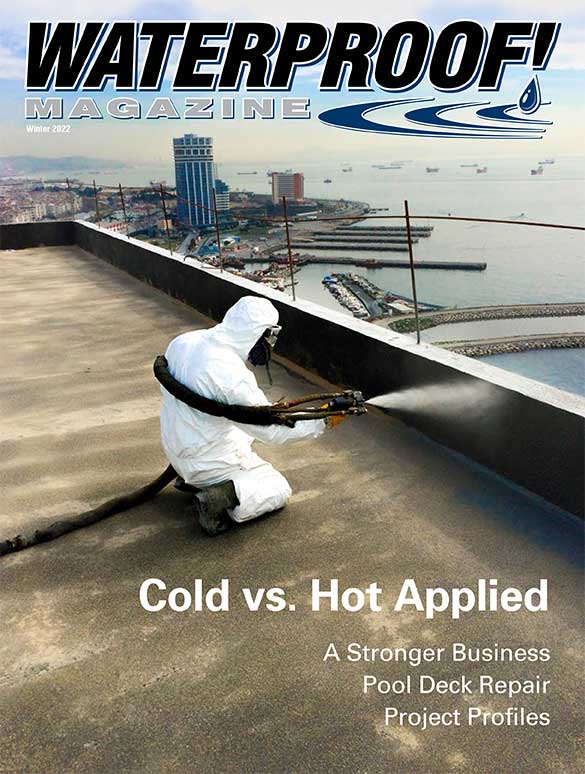

Cold Vs. Hot-Applied Liquid Applied Membranes and Coatings

Insulfoam’s Geofoam Completes Swimming Pool

Waterproofing Pool Decks

Largest Waterfront in the Southeast

Roofing Collaboration For Shriner’s International Project

Strengthening Your Waterproof Business

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Cold Vs. Hot-Applied Liquid Applied Membranes and Coatings

By Greg Austin

An expert in liquid applied membranes and coatings discusses the unique set of features and benefits to cold-applied and hot-applied waterproofing products. Which type is more durable?

Insulfoam’s Geofoam Completes Swimming Pool

The massive Midtown 360 425,000 square foot complex was designed to accommodate both residential and commercial real estate needs. And a major draw for potential residents is a luxurious outdoor swimming pool on the first floor of the building.

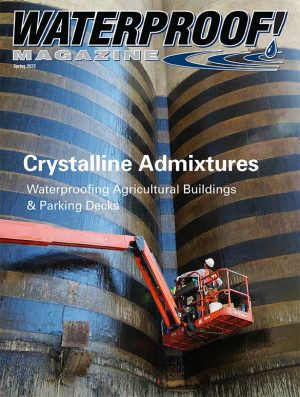

Waterproofing Pool Decks

By Vanessa Salvia

Concrete is more vulnerable than it seems, especially when it comes to water damage. Since a pool deck is constantly exposed to water, one of the first signs of damage to appear is cracks.

Largest Waterfront in the Southeast

By Meredith Cook

The city of St. Petersburg welcomed Floridians to a revitalized 26-acre attraction—St. Pete Pier. Serving as a premier destination for residents and visitors alike, the new pier hosts amenities ranging from an open-air market to performance spaces.

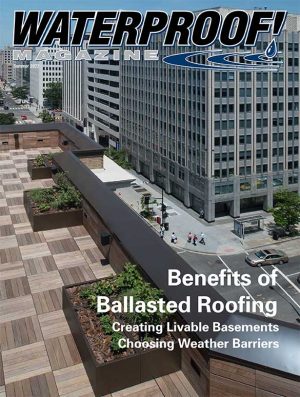

Roofing Collaboration For Shriner’s International Project

Polyglass U.S.A. Inc., a leading manufacturer of roofing and waterproofing systems, teamed up with D&D Roofing, a roofing contractor in Nevada, to provide a new roofing system for a Shriner’s Kerack in Reno.

Strengthening Your Waterproof Business

By Vanessa Salvia

The world has changed. Because of COVID and how that limited in-person interactions, yes, but even before that, online interactions were becoming more commonplace. So what can waterproofing companies do to keep themselves visible and relevant? Here are some ideas.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|