By Greg Austin

Photos courtesy of GCP Applied Technologies

Waterproofing solutions for commercial construction projects come in a variety of materials or chemical make-ups, from the asphalt-based products of traditional solutions to advanced technologies such as polyurethane, PMMA (polymethylmethacrylate), and polyurea.

Liquid-applied waterproofing is a popular solution for horizontal deck applications. This application is evolving as technologies improve and a wider variety of systems and manufacturers populate the category. There are hot-applied liquid waterproofing solutions made of vulcanized rubber such as hot rubberized asphalt (HRA), and cold-applied liquid waterproofing solutions made of polymers such as thermoplastic elastomers, or polyurea.

An elastomeric waterproofing material such as GCP’s Silcor liquid waterproofing line offers advantages over other technologies due to its flexibility to expand and contract; its durability prevents punctures, indentations, and abrasions, and it is able to withstand high tensile forces. Because of the demands made on waterproofed surfaces in commercial building and construction environments, it’s critical that the material chosen for a waterproofing project have elastomeric qualities.

The Advantages of Flexibility

An elastomer is a polymer that has elastic properties similar to natural rubber. A liquid waterproofing solution that is elastomeric is highly flexible, and can provide the following waterproofing advantages.

Crack Bridging

Having the ability to expand and contract allows an elastomeric waterproofing material to accommodate a building’s or a surface’s structural movements and bridge cracks caused by concrete shrinkage.

The ability to perform crack bridging is essential with liquid waterproofing materials due to the natural dynamic movement of buildings and structures that creates cracks. In climates with temperature changes from season to season, especially down to low ambient temperatures, these cracks can shift, open, and close. This back and forth movement of cracks as temperatures change can create many fatigue cycles for the waterproofing membrane.

An elastomeric, cold-applied liquid waterproofing membrane is able to withstand building movements and fatigue cycles, maintaining its integrity over a long period of time and protecting the structure underneath by preventing any water from getting through.

Damage Resistance

The durability of the waterproofing materials — the resistance to punctures, indentations, and abrasions, and ability to withstand tensile and other mechanical forces — is a major consideration when choosing a liquid waterproofing solution.

There are specific criteria that should be assessed to determine durability performance:

Tear resistance or tear strength – The resistance to tearing action, including the force to initiate tearing of the materials or tear propagation. With a waterproofing application, the high force required to initiate the tearing is particularly important to prevent breach formation .

Shore hardness – The resistance of a material to indentation and heavy loads.

Abrasion resistance – The ability to handle numerous cycles of abrasion on the surface before wearing down or rubbing away by means of friction.

Most elastomeric, cold-applied liquid waterproofing solutions are systems made up of reactive ingredients that can react to form a high molecular weight or cross-linking polymer, providing strong resistance to puncture, indentation, wear and tear, etc. Exposed waterproofing or the waterproofing protection course should stand up to any foot traffic or construction activity. This is especially critical when heavy equipment is moved, resting, or even dropped on the surface, which may break the concrete underneath. Silcor liquid waterproofing can stay intact and prevent water penetration even when the concrete deck below the membrane is fractured.

The reactive, elastomeric, cold-applied liquid waterproofing also gives it the ability to handle “point loads,” such as from a heavy piece of equipment with narrow legs underneath. In such an instance, the membrane will not show a dent or penetration. Up to 3,000 psi point load has been tested on elastomeric, cold-applied liquid waterproofing without causing a single dent on the membrane.

Silcor liquid waterproofing can stand up to trade damage, extremely heavy loads, and a high number of cycles of abrasion, providing superior durability when compared with other liquid waterproofing products.

Elongation Capabilities

An elastomeric, cold-applied liquid waterproofing solution’s flexibility combined with its tensile strength enables it to withstand stretching beyond the point where other (particularly hot-applied) liquid waterproofing solutions might break.

Fewer Applications – No Reinforcement

As a result of its elastomeric qualities, cold-applied liquid waterproofing requires only one to two layers to achieve reliable and durable performance. The use of an inter-layer reinforcement is not required to maintain the integrity of the waterproofing membrane. Additionally, a protection course is not necessary during construction.

Disadvantages of a Non-Durable Membrane

Waterproofing systems that lack the flexibility and durability of an elastomeric waterproofing system require multiple layers, along with reinforcement layers and a protection board. This adds complexity and the potential for errors to occur during installation.

Since asphalt-type, hot-applied liquid waterproofing is composed of a large proportion of low and medium molecular weight ingredients, it can handle only limited loads or cycles of abrasion on its surface before showing wear, dents, or penetrations.

Hot-applied liquid waterproofing is flexible under install conditions but then hardens in place as it cools. In cold climates, hot-applied liquid waterproofing can handle exposure down to 0° F but becomes brittle at lower temperatures.

These are all very good reasons why the waterproofing material’s properties and chemistry should be given serious consideration when choosing a waterproofing system.

Conclusion

Liquid waterproofing solutions must have certain characteristics to perform effectively, specifically flexibility and durability. Solutions containing polymers that are elastomeric, such as GCP’s Silcor liquid waterproofing line, provide flexibility and strength that ensure its durability, enabling performance that is critical to long-lasting waterproofing and protection of the substrate surface. An elastomeric waterproofing material is physically tough enough to handle construction site abuse and long-term aging while maintaining its waterproofing integrity.

With an elastomeric liquid waterproofing solution, builders and architects can trust they have a superior and efficient waterproofing system that is durable and long-lasting and will reliably seal and protect surfaces and structures from water penetration.

Greg Austin

The global product director, specialty building materials, for GCP Applied Technologies. He has a background in consulting and almost a decade of experience in waterproofing system development and construction materials.

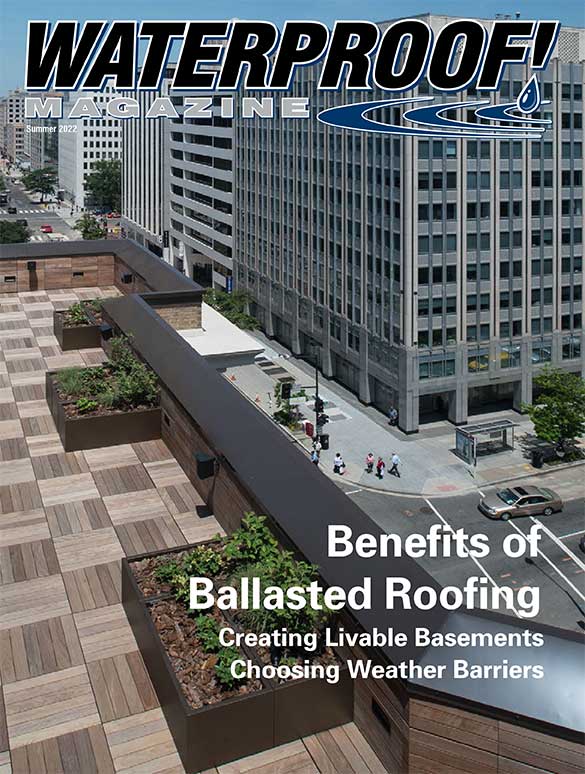

Summer 2022 Back Issue

$4.95

Creating Livable Basements

Benefits of Ballasted Roofing

Why Your Waterproofing System Should Be Elastomeric

Choosing the Right Weather Barriers

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Creating Livable Basements

By Vanessa Salvia

In homes that have a basement, an increasing number of homeowners are turning them into livable spaces like living rooms and bedrooms or offices. This makes the air quality even more important because people are using them for extended periods of time now.

Benefits of Ballasted Roofing

By Vanessa Salvia

A ballasted roof is a roof in which the roofing membrane is not anchored or adhered to the decking material but is instead held in palace by rocks or pavers. These roofs work even during high wind events, and they have other advantages too.

Why Your Waterproofing System Should Be Elastomeric

By Greg Austin

Waterproofing solutions for commercial construction projects come in a variety of materials or chemical make-ups. An elastomeric waterproofing material offers advantages due to its flexibility, durability, and high tensile strength.

Choosing the Right Weather Barriers

By Errol Bull, P.E., CSI

Whether it’s blazing heat and torrential downpour, or harsh winds and icy snowfall, buildings must withstand a range of extreme conditions, year after year. So, how do we make sure that our buildings are built to last?

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|

Greg, what a well-researched article! Elastomers can create incredibly thick exteriors to avoid leakages. They work on all materials like brick, metal, and concrete. Elastomeric paint is durable as well which makes the waterproofing system all the more efficient.