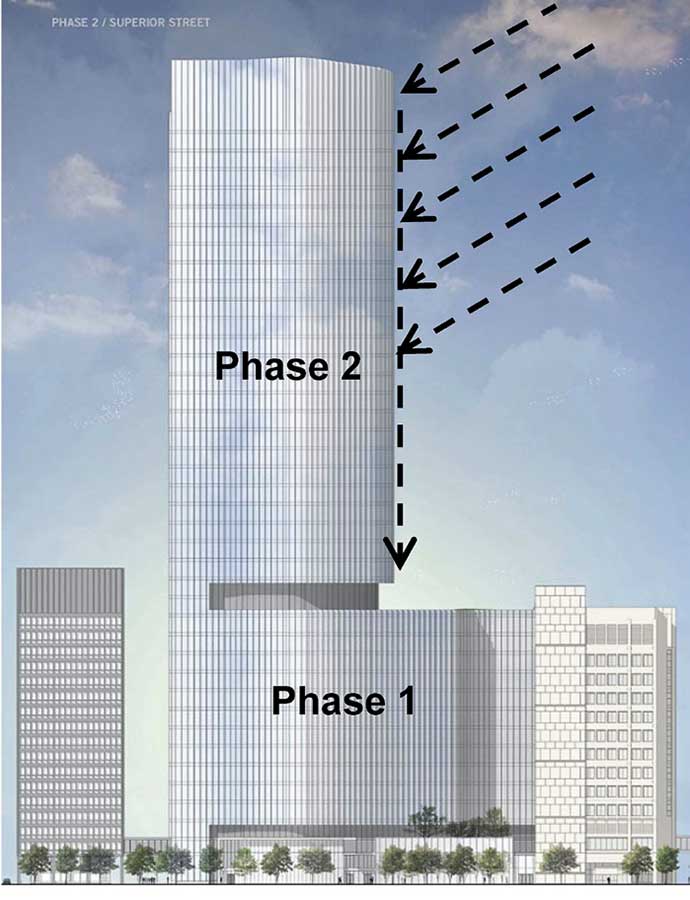

The city required that green roofs be installed on the upper roofs of the Phase 1 structure. Phase 2 will consist of a 20-story tower constructed on top of the 250-foot tall Phase 1 structure.

Located in the Streeterville area on the north side of Chicago, the Northwestern University Simpson Querrey Biomedical Research Center is the newest medical building in the Northwestern University medical campus. A privately-funded cancer research center, the major addition to the Chicago medical community was designed by the Chicago office of Perkins+Will (P+W) and its sub-consulting team.

The proximity to Lake Michigan creates a high water table issue for the building. It is also in a dense urban area. The city of Chicago Department of Water Management required that a minimum of 10,000 cubic feet of stormwater be managed on the project. P+W and Hydrotech created solutions using Hydrotech’s Garden Roof Blue Roof Assembly to put that stormwater on the top two roof surfaces of the Phase 1 structure, consisting of the base building of 14-stories plus two underground basement stories.

In addition, the city required that green roofs be installed on the upper roofs of the Phase 1 structure. Phase 2 will consist of a 20-story tower constructed on top of the 250-foot tall Phase 1 structure.

The project was required to accommodate the stormwater volume generated by the “critical side wall” of the future Phase 2 tower of the project.

Hydrotech’s Garden Roof Blue Roof Assembly was selected to address all of these conditions. The Blue Roof assemblies covered the entire area of Levels 13 and 14. Pavers and Garden Roof assemblies cover the Blue Roof components on these levels.

The roof decks for the blue roof areas were constructed in concrete with a zero-slope. This allowed for optimum water detention volume across the roof surface. Hydrotech’s Monolithic Membrane 6125 (MM6125-FR) was used to waterproof the roof surfaces to protect the building. Given the depth of the Blue Roof assembly, flashings were raised to higher levels on penetrations and other elements that came through the deck structure. Once the MM6125-FR and protection sheet work was completed, the installation of the various overburden components commenced.

The Permavoid units are installed in a single layer on top of the finished Styrofoam thermal insulation.

Upon completion of the Permavoid layer and concurrently with the paver installation, the extensive Garden Roof was constructed over the Permavoid.

Making a Place for the Water

Creating a blue roof involved providing a place for detaining the stormwater. For this project, Hydrotech provided Permavoid (manufactured by ABT Plastics). Permavoid consists of a plastic voiding component, approximately 14x28x6-inch thick, which generates a voided volume of approximately 90 to 95%. The structure of Permavoid allows for detention of “free water” (water not bound-up with growing media or aggregates) within the Permavoid units. This stormwater can move freely through the Permavoid units across the roof space.

The Permavoid units are installed in a single layer directly on top of the finished Styrofoam thermal insulation. The Permavoid units are connected together with dovetail connectors to create a firm surface on which other components can be installed. The Permavoid units were easily cut to fit with the odd spaces typical on any rooftop installation.

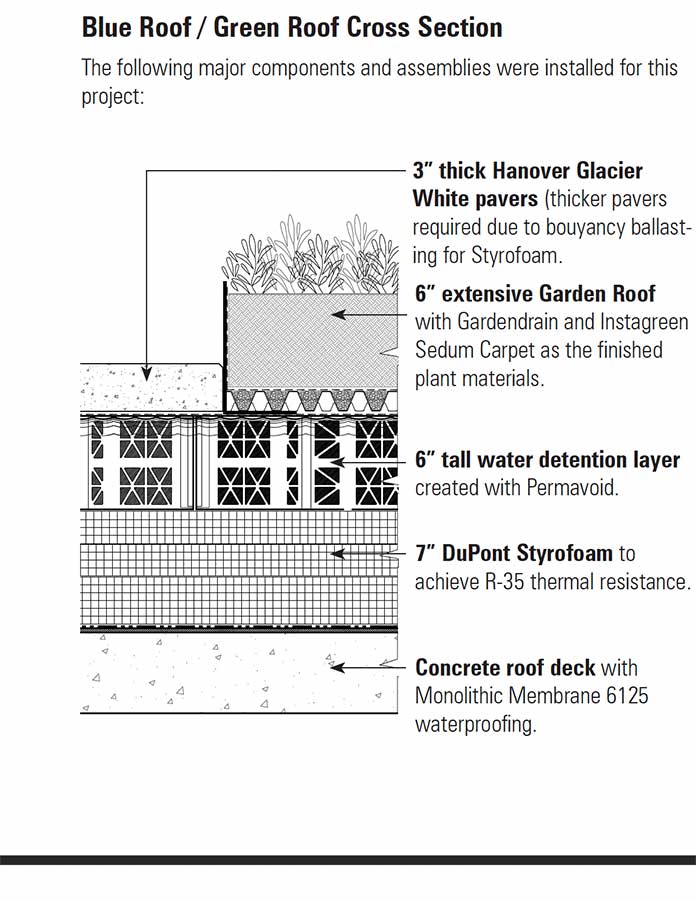

The following major components and assemblies were installed for this project:

- 3” Hanover Glacier White pavers (thicker pavers required due to buoyancy ballasting for Styrofoam.

- 6” extensive Garden Roof with Gardendrain and Instagreen Sedum Carpet as the finished plant materials.

- 6” tall water detention layer created with Permavoid.

- 7” DuPont Styrofoam to achieve R-35 thermal resistance

- Concrete roof deck with Monolithic Membrane 6125 waterproofing.

Finishing with the Green

A layer of Gardendrain was installed first which was covered by a filter fabric and then filled with Hydrotech’s LiteTop engineered growing media. Portions of the Garden Roof adjacent to the perimeter were reinforced with Checker Block to aid in the wind resistance of the Garden Roof.

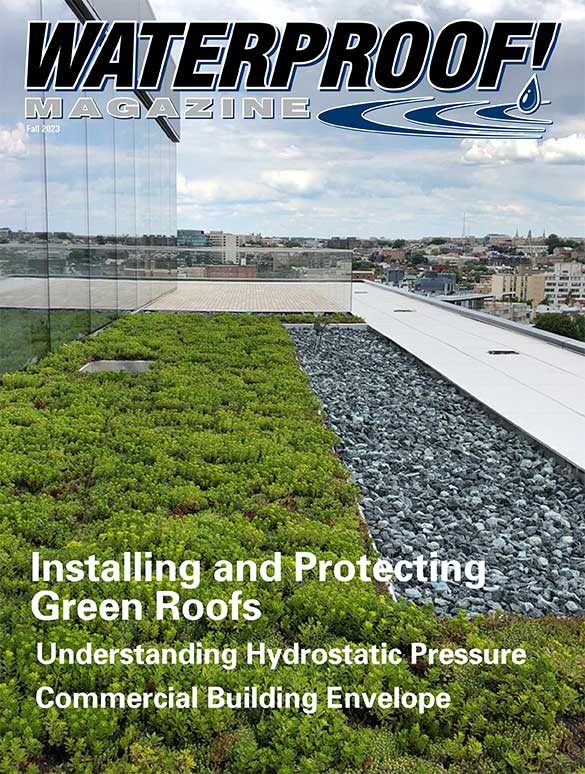

Fall 2023 Back Issue

Price range: $4.95 through $5.95

AI in the Waterproofing Industry

Case Study: Northwestern University’s Simpson Querrey Biomedical Research Center

Installing and Protecting Green Roofs

Protecting the Commercial Building Envelope

Understanding Hydrostatic Pressure

Employer Responsibilities To Employees and Law

By Gregory Fahrenbruch

Description

Description

AI in the Waterproofing Industry

By Vanessa Salvia

It may be something you have to get used to, but once you do, it could be extremely useful and valuable.

Case Study: Northwestern University’s Simpson Querrey Biomedical Research Center

By American Hydrotech

The building’s proximity to Lake Michigan creates a high water table issue for the building.

Installing and Protecting Green Roofs

By Vanessa Salvia

There are many benefits of green roofs. However, successfully installing and maintaining a green roof requires careful planning and protection to ensure the plants thrive.

Protecting the Commercial Building Envelope

By Vanessa Salvia

Envelope performance directly impacts occupant comfort, health, energy efficiency, durability, and operating costs.

Understanding Hydrostatic Pressure

By Vanessa Salvia

When water accumulates and cannot drain properly, hydrostatic pressure builds up and pushes against the waterproofing membrane or material.

Employer Responsibilities To Employees and Law

By Gregory Fahrenbruch

Employers responsible for asbestos-related issues differ from those who do not work with asbestos but may have a potential for exposure to those who work abating asbestos products.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |