By Vanessa Salvia

Photos courtesy of GCP

GCP’s PrePrufe waterproofing system was used on the Golden 1 Center in Sacramento, California.

The complete building envelope from all six sides plays a critical role in both commercial and residential structures, because it serves as the primary barrier between indoor and outdoor environments. An effective envelope is crucial for controlling heat flow, moisture infiltration, air leakage, and sound transmission. Envelope performance directly impacts occupant comfort, health, energy efficiency, durability, and operating costs. Waterproofing and air barriers are a vital component in creating an envelope that provides protection from liquid water intrusion while also meeting other performance requirements.

Commercial vs. Residential Envelopes

While the building envelope serves the same purpose on both residential and commercial structures, there are several key differences between the two.

- Materials – Due to scale and intensity of use, commercial envelopes often require robust and durable materials that can withstand wear and tear, such as concrete, steel, and glass curtain walls, versus wood framing and siding that are more common in residential buildings. Residential building envelopes are designed to be durable as well, but maintenance might be easier to manage due to the smaller size and generally fewer occupants.

- Size – Commercial envelopes are much larger in scale given the bigger building footprints. This increases vulnerability to elements.

Exposure – Commercial buildings may endure more environmental exposure with less shelter from other structures. Residential homes may have more protected exposures. - Function – The envelope of a commercial building needs to accommodate more complex and diverse uses such as offices, retail, factories, warehouses, etc. These commercial buildings often have specific requirements for insulation, ventilation, lighting, and structural integrity that are tailored to their functions.

- Lifespan – A commercial envelope is designed for decades of continuous use, while a residential one may see periods of vacancy or less wear.

- Loads – Commercial envelopes support greater structural loads for larger spans, higher stories, and heavier use. Residential loads are lighter.

- Energy use – The envelope of a commercial building plays a bigger role in minimizing energy costs for heating and cooling versus residential due to scale and continuous uses.

- Standards – Commercial construction must meet specific building codes, regulations, and standards that govern factors like fire safety and energy efficiency. Residential buildings may also need to adhere to building codes and regulations, but specifics may differ due to the distinct nature of usage.

- Risks – The risks of liability for the contractor increase along with the larger size and more complex designs of commercial buildings.

Effective waterproofing is critical to withstand these demands over decades of use.

The Importance of the Commercial Envelope

The building envelope is one of the most critical components of a commercial structure and impacts almost all aspects of building performance. A high-quality envelope serves to protect assets by controlling liquid water, humidity, air infiltration, and chemicals — preventing damage to the structure, finishes, contents, and occupants while preserving property value. It also reduces operating costs by limiting unconditioned air exchange and thermal transfer, thereby minimizing energy consumption for HVAC and lowering utility bills.

GCP’s PrePrufe Plus waterproofing system is applied to provide optimal protection to this deep foundation on the Golden 1 Center.

Geographic Location and Commercial Materials

Lindsay Castles, president of GMX Inc., a waterproofing and air barrier product manufacturer, notes the variety of products available for commercial buildings. “Location and construction timing impact material choices, with options like fluid-applied membranes, fully adhered sheet membranes, and swellable technologies influencing decisions,” Castles says. “For commercial projects, multiple products from various manufacturers have been historically common for different aspects like foundation waterproofing and weather resistant barriers. Seeking a single manufacturing source, offering a complete package for the entire envelope, is the evolving trend to ensure compatibility and success.” In the residential realm, this concern is less pronounced.

Castles says that the first thing to do to make a decision about your commercial materials is to look at the specific application, the end use of the building, how the product works, and what the goals are of the building. In the commercial building world, it is common to have numerous products from a variety of manufacturers that might be used in various aspects like foundation waterproofing and weather barriers, however, it’s more common to seek out a single source of manufacturing due to increased assurance when it comes to compatibility of different application materials. “There’s a bigger push to have the same manufacturer supply both the above-grade air barrier as well as the below-grade product,” he says. “They are different products, different systems, but there’s a little less concern about that in the residential world.”

Function

Iltaz Alam, a product manager at GCP, says one of the main differences is that many commercial buildings, such as hospitals, airports, or hotels, are designed to function 24 hours a day. “Energy consumption in a commercial building is higher than in a residential building,” Alam says. “Constructing a commercial building that is energy efficient becomes much more critical. Poorly designed envelopes that allow air leakage can result in energy wastage, leading to higher utility costs and increased carbon emission. You have to make sure that each and every element of your building envelope is sealed properly, so that you can protect what is inside the building.”

There are six sides of a building that all have to be waterproofed: the four walls, the roof, and the basement. “The waterproofing barrier materials you are selecting have to be compatible with each other,” Alam says. “For example, if there is any gap or the tie-ins are improperly done between where the foundation waterproofing connects to the air barrier, you are allowing the external elements like air and vapor to intrude into your building. Same goes for connecting the air barrier to the roofing waterproofing.”

In a very hot and humid environment where you would be running an air conditioner 24 hours a day, for example, or in a colder environment where you would be running a heater inside your building all day, restricting air and moisture movement becomes very critical and if there is any dampness, indoor air quality will deteriorate and may affect the health of occupants.

Choose Quality Materials

Alam says that when selecting materials for the commercial structure, the material performance track record is very important. “Look at the track record of the material which is being used in similar applications in similar conditions and see how it has performed over the years,” Alam says. “It gives a peace of mind to the owner that they are selecting something which has been used successfully for several years in a similar environment and they would not have to worry about its durability or performance during the life of the structure.”

The GCP Perm-a-Barrier portfolio offers both permeable and non-permeable solutions to meet the range of factors on a given project, including regional climate, wall design, compatibility with other materials, insulation placement and interior conditions.

Track record and long-term testing information can be obtained by request from the manufacturers. The architect, building envelope consultants, or the contractors are always free to request project references and other third-party testing. “Let’s say product A is being proposed,” says Alam. “The owner, contractor, or designer can always go back and ask for details such as how long the product has been in the marketplace, how many projects it has been used on, in which geographic region the products have been used and what type of long-term testing is available. The manufacturer should provide this information on request.”

The Bottom Line

When designed for durability and resilience with low maintenance needs, the building envelope components can extend the useful service life of the overall structure. Following best practices for the envelope also reduces potential issues like water damage, structural fatigue, equipment failure, or mold growth that could incur major costs due to repairs or liability.

Fall 2023 Back Issue

$4.95 – $5.95

AI in the Waterproofing Industry

Case Study: Northwestern University’s Simpson Querrey Biomedical Research Center

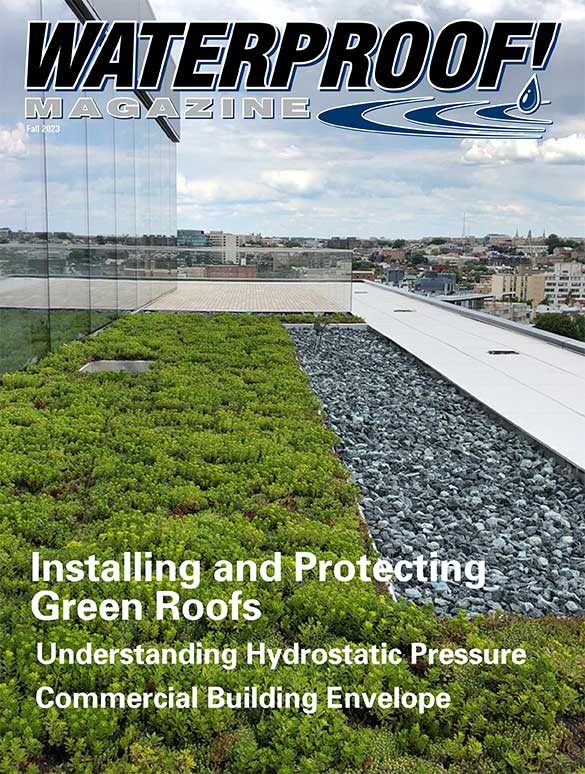

Installing and Protecting Green Roofs

Protecting the Commercial Building Envelope

Understanding Hydrostatic Pressure

Employer Responsibilities To Employees and Law

By Gregory Fahrenbruch

Description

Description

AI in the Waterproofing Industry

By Vanessa Salvia

It may be something you have to get used to, but once you do, it could be extremely useful and valuable.

Case Study: Northwestern University’s Simpson Querrey Biomedical Research Center

By American Hydrotech

The building’s proximity to Lake Michigan creates a high water table issue for the building.

Installing and Protecting Green Roofs

By Vanessa Salvia

There are many benefits of green roofs. However, successfully installing and maintaining a green roof requires careful planning and protection to ensure the plants thrive.

Protecting the Commercial Building Envelope

By Vanessa Salvia

Envelope performance directly impacts occupant comfort, health, energy efficiency, durability, and operating costs.

Understanding Hydrostatic Pressure

By Vanessa Salvia

When water accumulates and cannot drain properly, hydrostatic pressure builds up and pushes against the waterproofing membrane or material.

Employer Responsibilities To Employees and Law

By Gregory Fahrenbruch

Employers responsible for asbestos-related issues differ from those who do not work with asbestos but may have a potential for exposure to those who work abating asbestos products.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |