By Aaron King

Photos courtesy of Aaron King

EcoFinish is a highly durable and UV-stable thermoplastic powder coat. This method requires the most bespoke equipment and skill sets.

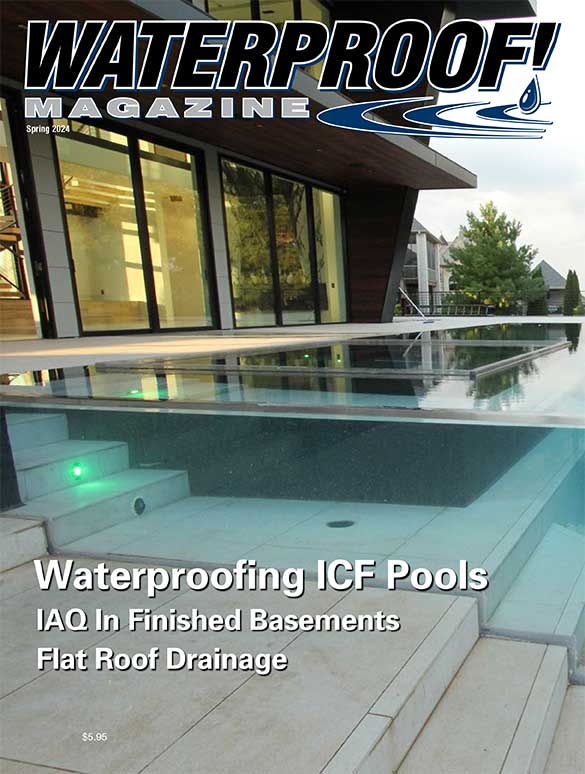

In a world where ICFs (insulated concrete forms) have rapidly made their way into the mainstream from single-family homes to multistory commercial and schools, one area of huge growth has more potential than all the others, but that potential comes with many technical challenges: Pools. The pool market in general saw huge percentages of growth over the past three years. Low interest rates coupled with less ability to travel caused people to reevaluate investing in their own private sanctuaries in their backyards. ICF pools gained immense popularity in that time due to several factors ranging from far superior thermal efficiency to structural superiority.

ICF pools are up to three times cheaper to heat when compared to their traditional counterparts. For many though, it is the ability to forgo the traditional route of hiring a local pool contractor and handling the build themselves, either by contracting out the various phases of the build or going the DIY(do it yourself) route. ICF pools come out ahead in all the above areas for many of the same reasons it has gained wide acceptance in general construction, but with pools there is one detail that must be addressed with knowledge and attention to detail far greater than a traditional ICF structure such as a foundation: waterproofing! ICF pools must hold immense amounts of water and pressure. Unlike most foundation walls that simply need to direct run off into the subgrade drainage, the requirement of ICF pool walls is to create an impermeable vessel that is not only waterproof but also highly resistant to the many chemistry- and temperature-related changes a pool is likely to go through throughout the year. Below are four products that we have used with consistent success at every price point, and a couple of things to watch out for when selecting your pool finish.

Choose Proven Products

First, here are the products that we know work: vinyl liners, Renolit PVC membranes, Basecrete/Skin Microplaster, and EcoFinish.

Vinyl liners are the least expensive option for waterproofing a pool. They are the easiest for DIY-ers or new builders to accomplish, but fade over time due to exposure to UV rays and chlorine.

Vinyl Liners

Vinyl liners are the least expensive of the four options, but they are a great option for the average residential pool and they are the easiest for DIY-ers or new builders to accomplish. Liners come in a variety of colors and patterns and thicknesses from 20 to 27 mils. They are fairly inexpensive and typically last 10 to 15 years and replace easily. Another plus for liners and PVC membranes is that the structure of the pool is not as crucial because the liner does all the work of holding the water. Non-liner versions must have much more robust structures to ensure zero movement in the shell. ICF vinyl liners are up to three times more efficient compared to steel wall vinyl liners and far more structurally robust.

The downsides to liners are that they fade over time due to exposure to UV rays and chlorine. Liners are the cheapest of all the options when it comes to replacement, although you will likely replace liners a little more often than the more expensive options.

Renolit PVC Membranes

Renolit PVC membranes are a 70 to 80 mill site-welded commercial-grade liner that have been heavily used in the Middle East and Europe for years, but have gained favor in the US more recently as an affordable option for large or commercial applications. Like vinyl liners, they come in several colors and patterns, but the colors are more stable and resistant to fading. These liners are also site-welded, similar to a TPO (thermoplastic overlay) commercial roof, so in addition to the higher material cost compared to vinyl, the labor to install is also greater. The installed cost of a Renolit membrane is probably three times the cost of vinyl, but you can expect in excess of 20 years of life and far more resistance to tears and punctures, making it ideal for commercial pools and competition pools.

This method is not as DIY-friendly as it takes some training and some professional-grade heat guns made for roofing, but most areas will have a qualified Renolit dealer that can install your project for you. It’s a great option for pools that have higher traffic but don’t quite have the budget or need of a plaster or EcoFinish.

Basecrete and Skin Microplaster

The ’cretes are the first non-liner option. While there are multiple ways to successfully build a non-lined pool, we personally choose a monolithic pour method when building any pool without a liner to limit cold joints in our concrete that might exacerbate movement and create an easy point of failure. Monopour ICF pools are similar to traditional gunite pools in that they are one-piece concrete shells, with the added benefit of ICF insulating the shell and ensuring rebar placement does not move during concrete placement.

There have been many different systems developed for plastering over ICF for pools. The main ones we’ll discuss are Basecrete and Skin Microplaster. Basecrete is a type of waterproof polymer-modified stucco used in multiple different applications. While not specifically developed for pools, it has had success, especially as a base coat for other products. Fox Blocks (a well known ICF block manufacturer) specifies their preferred method of waterproofing non-lined pools is to install two layers of Basecrete with fiber mesh lathe entrained in the middle, and then use a traditional pebble finish plaster over the top. When done correctly this method should work well and the talent pool of installers is vast with the install being akin to stucco, you are paying for two finishes, which may make this method more costly in the end than the next version of this install, Skin.

Skin Microplaster is a newer product in the U.S., though it’s been successfully implemented in Italy for the past six years. Skin is a live polymer-synthetic waterproof plaster. Like Basecrete, Skin is a resin/cement–based plaster with the benefit of being specifically formulated for pools. Skin aggregate is micro-bead porcelain where the color is impregnated into the aggregated powder itself, giving you high degrees of color consistency between batches. While Skin was developed in Italy, the creator of Basecrete designed and supplies the liquid live polymer (magic milk) for the system. Skin is expensive for plaster, but you will not use as much as you will of traditional plaster over Basecrete.

Skin Microplaster is a resin/cement–based plaster with the benefit of being specifically formulated for pools. Skin can be difficult to install without some masonry experience.

Skin is applied by building two layers of Skin base with fiber mesh in between just like Basecrete, but then only one layer of Skin needs to be applied at 1/16 of an inch to ensure a waterproof shell. This method of plastering ICF is preferred on our installs as it has far better chemical resistance than traditional plasters. The reasons people go with a non-lined pool are durability and architectural features such as negative edges and weirs, which are difficult and clumsy with liners. And the limits of plaster are only the imagination of the builder and the skill of the installers.

These products are not DIY friendly without some experienced masonry help. A minimum of three installers need to work continuously to get to logical termination points, and it can be a taxing job if you haven’t done it before.

EcoFinish

The last coating we have had success with is EcoFinish. EcoFinish is a highly durable and UV-stable thermoplastic powder coat. It is installed with a proprietary flame-throwing coating machine that produces a lot of excess heat, with its 800,000 BTU burner, that is not good for traditional ICF. While early on we did install EcoFinish on several two-sided ICF pools, including my own with our own method of fiberglass priming the walls, we ultimately found that it was more economical to use a one-sided ICF form such as Nudura One, or BuildBlock Hardwall. At the moment these are the only two one-sided blocks, however several other companies are working on solutions for their block and there is even an aftermarket solution in development that will be specific to the pool industry. EcoFinish uses two coats of their own thermally stable epoxy to prime pool surfaces from concrete and plaster, to fiberglass and even steel. The flame then chemically and physically entrains the powder coat into and on the epoxy for a shell with unmatched durability and color stability.

This method does require the most bespoke equipment and skill sets, so it is not a DIY friendly product, however many installers are willing to install on a DIY ICF shell if properly cast and prepped.

The methods above all work extremely well when done properly. These finishes will give the same or better performance than they would on their traditional counterparts while giving up to three times better thermal efficiencies. There are, however, many coatings that have been tried and experimented with to mixed results. We feel that while we love to see innovation in the industry, there are several things to consider when choosing the finish for your pool. Epoxy paints do offer a fairly high level of waterproofing, but UV rays and the harsh chemistry of pool water tend to cause it to fail prematurely. We routinely see hotel pools that are 10 years old with four to five coats of epoxy paint.

Polyurea Coatings

A huge area of finishes which has gained ground in pool finishes is polyurea coatings. Polyurea is a two-part coating that can be chemically altered to give a premium finish in bed liners, garage and industrial floors, and many other applications. The unique challenges of full submersion and pool chemistry, especially chlorine, have proved problematic for polyurea as a pool finish. Some people have had some success with polyurea by utilizing AOP (advanced oxidation potential) systems on their pools.

This system combines a salt chlorine generator with UV light and ozone to cause the chlorine demand to drop dramatically, enabling you to run a pool on a very low amount of chlorine which enables the polyurea finish to sustain.

In the real world of pools, however, we feel that while AOP is a great system, any pool service tech hired to service the pool that sees dangerously low chlorine levels is likely to shock the pool to a higher level, potentially ruining the finish. With all the proven options, we feel that the risks far outweigh the rewards so far, although we know there are several well known polyurea coating companies working on solving those issues.

Pop-up Finishes And Newcomers

The third and most problematic finishes are the pop-up finishes and newcomers who experiment with pools without any proper testing and third-party verification that their science works. ICF in general has seen a rush of new contractors, and ICF pools are no different. When vetting any potential contractor for pools, you should do a lot of due diligence on the finish they are using. Good questions to ask are how long the coating has been around and what failure rates are typical. More importantly, ask what ASTM (American Society of Testing Materials) tests have been done on the system that would represent independent third-party verification that the claims of the finish are valid. When I reached out to EcoFinish, Basecrete, and Skin they all provided me with six to 10 ASTM tests from adhesion to abrasion resistance to color stability and chemical resistance. These tests represent hundreds of thousands of dollars in research and development dollars spent that not only let you know that the products have met a certain standard, but also lends some assurance that the company is capable of standing behind their product to a degree many untested, unproven startups cannot.

The two liners mentioned above also have a level of testing and history that we feel comfortable working with. While there will always be new inventions and products that can potentially revolutionize an industry, when it comes to pool coatings it’s generally better to stick with methods that are currently working until the newcomer products get to the same level of testing and safety.

ICF pools have come a long way in a short period of time. They are still misunderstood by many in the pool industry and the general public and failed finishes only work to exacerbate that issue. Seeking out training in proven methods and materials is always the best way to ensure your best chance for success in any endeavor and there are amazing resources available in the ICF pool world to easily access any level of training you need. When done properly, ICF pools should be around the same price point as their counterparts with superior per-

formance across the board.

Aaron King

Aaron King is the founder and president of All3 Pools LLC and Cutting Edge Pools in Springfield, Missouri, who built his first pool in 2008, teaching himself after starting to build custom homes in 2002. He built his first ICF home in 2013. Find him at www.icfguru.com and https://cuttingedgepools.com.

Spring 2024 Back Issue

Price range: $4.95 through $5.95

Indoor Air Quality in Finished Basements

Options for Waterproofing ICF Pools

Commercial Roof Drains and Drainage Systems

Description

Description

Indoor Air Quality in Finished Basements

By Andre Lacroix and Erika Lacroix

Creating livable spaces in basements is a trend on the rise, but take a moment and ask yourself, “Would I live in my finished basement?” What’s the latest, most up to date information you need in order to make the most informed decision for you and your customers?

Options for Waterproofing ICF Pools

By Aaron King

In a world where ICFs (insulated concrete forms) have rapidly made their way into the mainstream from single-family homes to multistory commercial and schools, one area of huge growth has more potential than all the others, but that potential comes with many technical challenges: Pools.

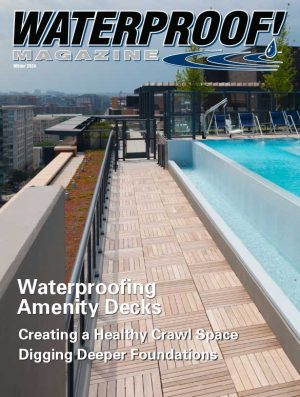

Commercial Roof Drains and Drainage Systems

By Iko Commercial

Commercial buildings often have flat or low-sloped roofs that need special drainage solutions. This article provides an overview of the types of drainage systems suitable for commercial buildings and the materials and components of those systems, and also covers what kind of maintenance a flat roof drainage system requires.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |