— Answers by Abby Feinstein, CertainTeed Director of Product Management

What Is Built-up Roofing?

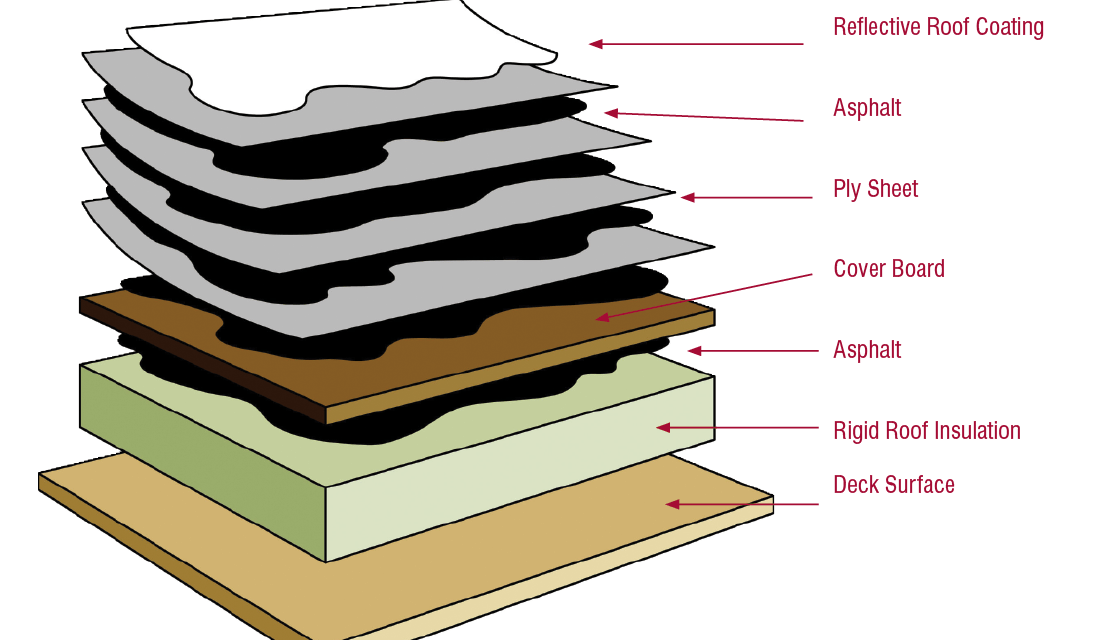

Built-up roofing or BUR is one of the oldest roofing methods still in use today. It consists of multiple layers of hot asphalt being applied between ply sheets thereby building up a waterproof roof assembly.

How is BUR different from other types of roofing systems?

The prevailing roof “assembly” in the market today is a single-ply. Typically, large-width thermoplastic or thermoset membranes are applied in a single layer by either a mechanical attachment/welding combination, field-applied adhesives, or factory-applied pressure-sensitive adhesive. BUR systems, in contrast, consist of a minimum of three, and more typically five, layers of waterproofing.

What are its advantages?

It is arguably the most robust roof assembly one could install from an asset protection perspective.

What are its disadvantages?

It is incredibly labor intensive and requires the use of hot asphalt, which has a higher health and safety risk profile than other roofing methods available today.

What are the best cases for the application of this type of roof?

Today we typically see aging roofers who came up installing BUR and maintaining that practice. Geographically, we see most activity tied to California and Florida.

Are there any situations where you would not use this type of roofing?

BUR is not a very popular roofing method today due to its labor requirements and association with hot asphalt. In the 1970s, manufacturers introduced modified asphalt membranes which were inherently waterproof, as compared to the BUR ply sheets, which require the field-applied hot asphalt to saturate and coat to create a watertight roof. The introduction of modified asphalt paved the way for 2-ply roof assemblies that offered a comparable level of waterproofing with significantly less labor. Over the last 20 years, within the modified asphalt space, membranes with factory-applied pressure-sensitive adhesive have vastly outpaced any other membrane that would require either a torch or cold/hot asphalt for application. Self-adhered modified asphalt roofing delivers the benefits of this tried and true multi-layer waterproofing system for a fraction of the labor and without fumes or flames.

— Answers by Ted Winslow, CertainTeed Commercial Building Envelope Product Manager

A basic outline of the process for installing a Built-Up Roofing System would include the following:

- Surface Prep – Ensure the roof deck is clean, dry, and free of any debris prior to installation and inspect for any damages and necessary repairs.

- Base Sheet Installation – This is a fundamental foundation layer for the subsequent layers. Insulation may also be incorporated into the system.

- Layer Application – Apply alternating bituminous layers and reinforcing fabrics (aka ply sheets).

- Interply Mastic and Flashing Installation – Mastics and sealants are applied between layers to ensure a strong bond, and flashings are incorporated around the roof edges, penetrations, and other areas to shed water away and reduce leaks.

- Final Surfacing – Add a top layer of aggregate material, such as gravel or stone to protect the underlying layers from UV rays and physical damage. This layer also provides fire resistance and durability. Cap sheets like Flintglas MS Cap Sheet can also be used to simplify the application process.

- Quality Assurance and Inspection – It’s important to follow up the installation with an inspection of the entire roof to ensure all layers are properly installed and bonded and to address any issues or defects.

Any new advances in techniques or materials in this area?

Several new advances have enhanced how many of these systems are applied and managed including:

- Cool Roofing Materials – Reflective coatings and surface treatments like Coolstar increase solar reflectance and thermal emittance, which helps to keep buildings cooler and reduce energy costs.

- Self-healing and Self-cleaning Materials – New coatings have the ability to repel water and dirt, which reduces maintenance needs and prevents mildew build up.

- Advanced Waterproofing Techniques – Roof coatings provide excellent waterproofing and can extend the lifespan of many BUR systems.

- Smart Roofing Technologies – Sensors can be used to detect leaks, monitor snow loads and alert building owners to potential issues before they become too serious.

- Robotics and Drones – Drones can be used for inspections, roof measurements, and damage assessments to enhance accuracy and safety.

Winter 2025 Back Issue

$4.95 – $5.95

Trade Show Preview

Blindside Waterproofing: Techniques, Challenges, and Advancements

Foundation Repair Using Push Piers And Helical Piers

The Commercial Built-Up Roofing (BUR) Systems

Built-Up Roofing 101 from CertainTeed

Description

Description

Trade Show Preview

Explore waterproofing-related businesses and educational sessions at the upcoming trade shows, including World of Concrete.

Blindside Waterproofing: Techniques, Challenges, and Advancements

By Vanessa Salvia

In urban construction and infrastructure projects, space constraints often necessitate innovative building techniques. One such method, blindside waterproofing, has become increasingly prevalent in recent years.

Foundation Repair Using Push Piers And Helical Piers

By Patrick Nevison, P.E.

This article takes a close look at helical piers and push piers, and explores the differences and uses of each type of foundation repair system.

The Commercial Built-Up Roofing (BUR) Systems

By Rose Morrison

Built-up roofing systems offer various options to meet different building needs and environmental conditions, with benefits that few other roofing types can match.

Built-Up Roofing 101 from CertainTeed

By Abby Feinstein and Ted Winslow

Built-up roofing or BUR consists of multiple layers of hot asphalt being applied between ply sheets thereby building up a waterproof roof assembly.

Carbon Fiber: The New Standard in Structural Repair for Basements

By Vanessa Salvia

In recent years, the field of basement and foundation repair has seen a significant shift towards carbon fiber technology.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |