by Brendan Bates

An A to Z guide on best practices

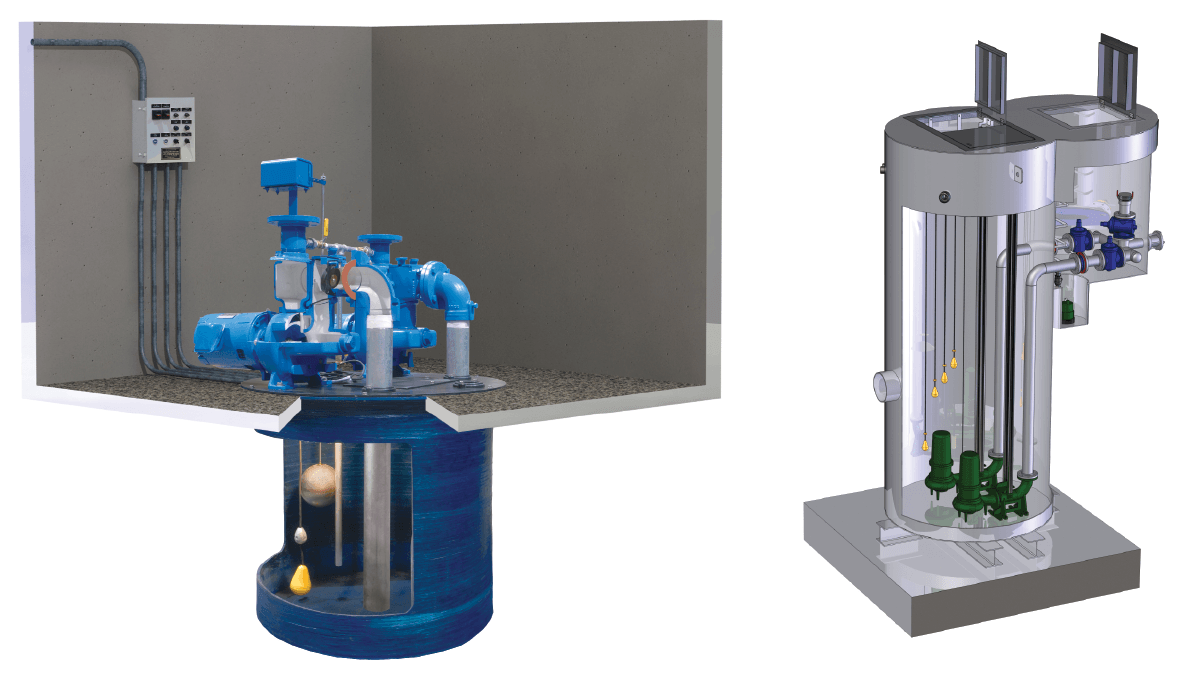

Variable speed controllers, such as this one from Metropolitan Industries, can significantly reduce costs, by reducing the size of the emergency stand-by generator, the sump, and the electrical cost associated with large-capacity pumping.

Introduction

According to the Federal Emergency Management Agency or FEMA, the number one natural disaster in the U.S. is flooding. Whether you are a homeowner or a business owner, a flood can wreak havoc on your property causing many thousands or millions of dollars in damage.

Many Americans understand what it takes to protect a residential basement from flooding; but when it comes to a commercial or industrial application there are drastic differences.

Commercial/industrial sump pump systems are a necessity for any commercial building with a basement. As you will read, commercial grade sump pump systems differ from their residential counterparts by the switching mechanism used, horsepower, control systems, style of pumps and more.

This article will discuss commercial and industrial sump pump system applications, types of pumps used, control systems, sizing of the wet well and variable speed pumping advantages.

Application Challenges

Many commercial/industrial applications requiring the installation of sump pump systems are large-scale facilities, which must be designed to evacuate subsoil drainage and/or surface water from the facility. Due to the large size of the facilities, the volume of water pumped is typically quite large. Because of this, a vast majority of these systems are designed as duplex arrangements, with two pumps in the same wet-well. If the application becomes excessively large, triplex or quadraplex systems can be installed as well.

Types of Pumps

Due to the large flow-rates being pumped, the physical size and weight of the pumps being provided becomes a major consideration. In order to facilitate ease of maintenance, the pumps provided are typically one of two different types: Floor-Mounted Self-Priming pumps, or Guide-Rail Accessible Submersible pumps.

Floor-Mounted Self-Priming pumps (above left) are the most common. They’re popular with design engineers and facilities management because the entire pump assembly rests above the wet-well in a clean, dry, accessible location. If the floor-space above the wet-well is required for other purposes, Guide-Rail Accessible Submersible pumps (above right) rest at the bottom of the wet-well on guide rails, which allow personnel to simply lift out the pumps using a chain or cable without the need to enter the hazardous-environment of the wet-well.

All pump maintenance and repair is accomplished without the need to lift the pump, or remove the pump from the piping.

Guide-Rail Accessible Submersible pumps are sometimes selected, especially if the floor-space above the wet-well is required for other purposes, such as a walkway or hallway. These pumps are submerged within the wet-well; however, they are installed with guide-rail systems, which allow the personnel to simply lift the pumps using a chain or cable to remove them from the wet-well without the need to enter the hazardous-environment of the wet-well to disconnect the pumps from the piping.

Typical Control Systems Utilized

High flow rates typically require large pumps with 3-phase motors and starters. These systems are designed to operate the pumps on a constant-speed basis. The typical duplex installation utilizes a duplex wall-mounted control panel, which includes dual circuit-breakers, starters, current-overload protection, and an integrated control-logic system which monitors the level-switches in the wet-well to control the operation of the pumps. Capabilities which are essential to the control-logic system include lights which indicate the failure of each of the level-switches, the status of each of the pumps, the status of any faults or pump-failures, and a high liquid level alarm. The control-logic system must be designed to override any level-switch failure, and continue uninterrupted automatic operation of the system, until the switch failure can be addressed. A majority of duplex pump systems utilize four level switches which are suspended at different elevations within the wet-well. The control-logic system uses the signals from these switches to start, stop, and alternate the pumps, as well as to signal a high liquid level alarm condition.

Appropriate Sizing of the Wet-Well

Pump systems which utilize motor-starters operate the pumps under constant-speed conditions. The pumps run at their rated speed, and lower the liquid-level to a particular level, and then turn off until the wet-well level rises again. The wet-well must be sized to retain a sufficient volume of water below the elevation of the inlet, in order to avoid ’short-cycling’ the pumps. Short-cycling occurs when the pumps turn on and off in rapid succession. This type of operating condition often leads to a build-up of temperature extremes within the pump’s motor. The build-up of heat, over an extended period of time, can lead to eventual motor damage, resulting in premature motor-failure.

In a majority of applications, it is important to design the wet-well to retain enough liquid below the inlet, to ensure that none of the pumps in the wet-well are allowed to start more than ten times per hour. For a typical duplex system, neither pump should start more than once every three minutes. Calculating the wet-well size can become a somewhat complicated process, because new liquid enters the wet-well while old liquid is being pumped out. An experienced pumping system sales-engineer or design-engineer should be consulted to verify proper wet-well sizing. It’s important to note that proper calculation methods can sometimes result in surprisingly large wet-well requirements.

Variable-Speed Pumping Advantages

The recent development of relatively low-cost variable-speed control systems has ushered in the use of this technology to solve a number of common operational problems typically associated with large-scale project applications: The advantage of using variable speed control includes reducing wet-well sizes, reducing the effects of large flow-surges, reducing the size of emergency stand-by generator systems, and reduce the electrical-costs associated with large-capacity pumping:

In many cases, properly calculating the wet-well size can result in massive wet-well sizes which can tend to be very expensive to purchase and install; or may not fit well within the geometry of the facility’s architecture. For these instances, it is often more logical and much less costly to utilize pump systems which use variable-speed control systems to operate the pumps. The use of variable-speed controls allows the size of the wet-well to be dramatically reduced; in many cases to a size which is amazingly small when compared to the traditional wet-well sizing method. When using variable-speed controls, the speed of pumps is modulated: controlled in such a way that the discharge-flow of the pumps exactly matches the flow of the liquid into the wet-well as closely as possible. During this modulation of flow, which may last for extended periods of time during major rainfall events, the pumps may run semi-continuously, thus eliminating the possibility of short-cycling completely.

During major rainfall events when extremely large pumps are cycled on and off at constant-speed, the wet-well is evacuated in large ‘surges’ of flow. This not only requires that the wet-well be excessively large to avoid short-cycling, but the surge-flow out of these pump systems often tends to exceed the capacity capability of storm-sewer systems down-stream of the pumping system. This can cause the storm-sewer systems to become over-taxed and may result in surcharged sewers. This becomes a catastrophe during major storms; at a time when gravity flow from other locations on the sewer-grid can least afford to be hindered. Major flooding of these gravity sewer grids may be the unfortunate result. In most instances, variable-speed pumping will eliminate this phenomenon, by creating a nearly-constant continuous flow of water, instead of major flow-surges.

Due to the critical nature of most large-scale sump pumping systems, it is desirable, or possibly essential, to have an emergency stand-by generator system provided for the pumping system, to ensure continuous availability of electrical power during times when power-outages are more likely. The kilowatt requirement and size (and therefore the cost) of these large equipment items can be greatly reduced on variable-speed systems, due to a direct reduction or elimination of high inrush amperage loads on the electrical gear.

Large pumps which require large motors, tend to create large electric utility invoices. The use of variable-speed controls reduces the electrical demand of the system, and therefore will reduce the cost of operation as well. The bottom line is a vast majority of projects which use variable-speed control systems, greatly reduce overall install cost, due to the cost savings associated with the benefits outlined above.

Even the most critical of commercial or industrial sump pump applications can be successfully addressed with the appropriate and properly-engineered pumping equipment and controls.

For more information about commercial/industrial sump pump systems, contact Brendan Bates at 815-886-9200, ext 257 or by email at bbates@metropolitanind.com.

Summer 2010 Back Issue

$4.95

Water Barriers to Withstand Shotcrete

Sump Pumps for the Commercial Market

Black or White: Roofing Color as an Energy Strategy

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Water Barriers to Withstand Shotcrete

Shotcrete is a popular choice for tunnels, deep foundations, and other blindside work. But getting waterproofing that’s tough enough to stand up to the abuse is a top priority.

Sump Pumps for the Commercial Market

The larger volumes of water, higher head pressures, and complex dewatering systems involved in commercial work make selecting the right pump for the job more difficult.

Black or White: Roofing Color as an Energy Strategy

While black roofing membranes usually do a great job keeping water out, they may also contribute to higher energy costs and the “urban heat island effect.” The solution may be a simple black-and-white decision.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|