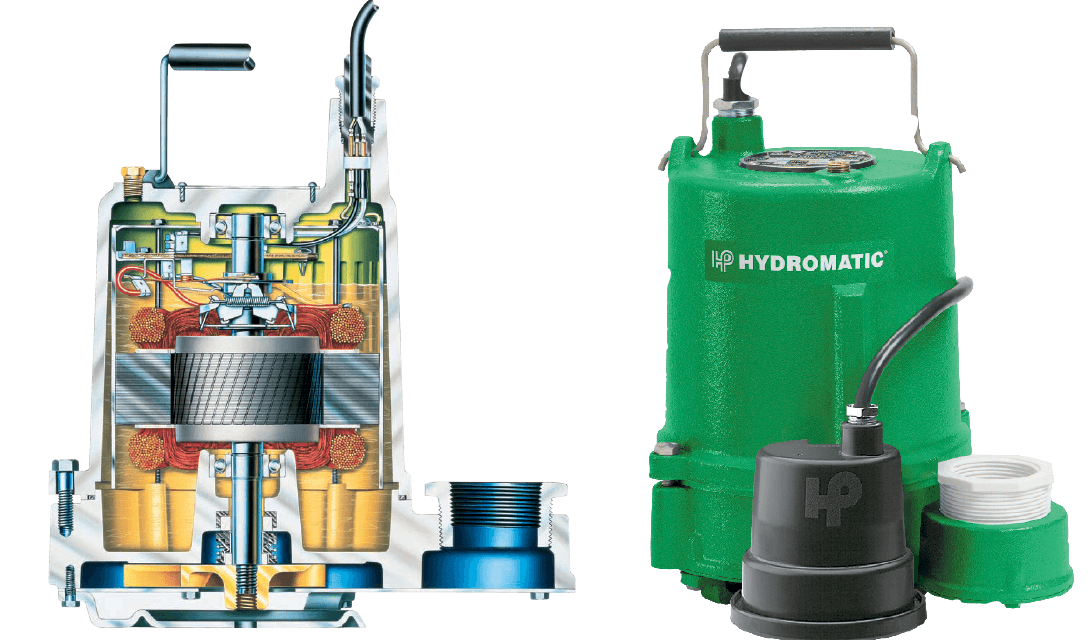

Heavy-duty submersible effluent pumps from Hydromatic demonstrates the high quality components used in commercial-grade equipment: The cutaway at left shows multiple strainer inlets, a bronze impeller mounted on a stainless steel shaft, top and bottom bearings, and an oil-filled motor.

Commercial grade sump pumps supply a vital need in areas where storms produce frequent flooding, or for businesses located in buildings with high ground water. Commercial grade sump pumps provide the extra muscle needed for excess water removal under flooding conditions.

Doug Shawler, technical service manager at Zoeller Company explains, “In situations where flow capacity is low, the construction and design of commercial pumps may be similar or the same as the residential pump model. However, commercial applications usually require higher volume pumps and stronger motors. Commercial pumps typically have 3-phase motors, higher flow capacities, larger solids handling, and larger inlet and discharge sizes.”

Construction

Commercial grade sump pumps operate at higher voltages than residential models. “Commercial/industrial sump pumps may require 3-phase power in 208, 230 and 460 volts,” Shawler warns.

Commercial-grade sump pumps usually use higher-quality components as well. “The longevity of operation associated with commercial grade sump pumps comes from the well- constructed contacts and high quality materials,” says Mike Bothwell, marketing communications manager at Hydromatic.

The exterior is typically high-quality cast iron, sprayed with epoxy or another durable corrosion-resistant coating. Internal components—including fasteners—are often made of stainless steel, and they’ll often have a vertical float switch (as opposed to the typical float arm on residential pumps.)

Many designs eliminate motor seals and rubber sealing boots. Fewer parts on any mechanical device can equal longer life since there are fewer mechanisms which can malfunction.

Shawler points out that commercial, municipal and industrial sump pumps are similar in design and performance. “Non-residential sump pumps have larger, more robust components to handle higher flow rates and larger solids,” he says. “Pump shafts, bearing systems and impellers have all been designed to give more performance over a longer period of time.”

Heavy-duty construction comes at a price, however. Commercial-grade sump pumps require a solid, balanced foundation; they’re never suspended from the ceiling or over the wet well.

Maintenance

But even the best-rated pumps need regular maintenance, and the more often the sump pump runs, the more often it needs to be checked.

Unlike residential sump pumps, which require little maintenance and are often sealed at the factory, commercial pumps should follow a regular maintenance schedule.

“Commercial pumps are designed to operate for many years,” says Shawler, “so service parts are readily available from the manufacturer. The operation and maintenance manual will provide accurate information about upkeep and service for sump pumps in this category.” It goes without saying that maintenance and repair, when required, should be performed by qualified pump mechanics. The pump manufacturer can provide a list of local authorized service providers.

In addition to the pump itself, the wet well or sump will need to be checked and occasionally cleaned out.

This commercial sump pump located at the Brookfield Zoo near Chicago, shows a typical floor-mount application. The twin pumps allow one to be shut down for maintenance while the other stays online. In high-flow situations, they can both be switched on.

Installation

A typical residential sump pit is one or two feet wide and twice as deep. A commercial/municipal wet well or pump station may be six or eight feet across—or larger—and as deep as needed.

“A typical commercial or municipal storm-water pump station can be equipped with two, three or more non-automatic sump pumps,” Shawler explains. “The sequence of operation typically has the pumps alternating to promote equal wear on the pumps and motors and also increases reliability.”

Often, these pumps are installed “in series” so scheduled maintenance on one doesn’t take the entire pumping station offline. It also allows building managers to bring additional pumps online during times of severe rainfall to increase the pump station’s capacity.

A control panel houses the pump power circuits and pilot control system. The power circuits are used to supply power to the pump motors. The pilot control system is responsible for the on/off points during normal operation and can activate additional pumps when needed. Multiple float sensors connected to the pilot circuit are used to define the on/off levels, activate additional pumps, and/or activate the high water alarm.

The circuits in the pilot control system are separate from the pump power circuits. This separation isolates the pilot circuit from the high energy levels in the power circuit and results in increased reliability for control and monitoring of the pump station.

The 280-series submersible sump pump from Liberty Pumps has a cast-iron body and the ability to pass solids up to ¾ inch in diameter.

Cost

Larger, better-quality pumps, larger volumes of water, higher head pressures, and complex electrical systems may add a few thousand dollars to the cost of a building.

But Bothwell, at Hydromatic, says installing an industrial sump pump is “the best thing you can do for yourself and your business.”

Consider what many businesses lose when their basements flood: office supplies and furnishings, computers, servers, electronic files, client information, even the building itself.

Each building owner has to weigh the cost of a sump pump installation against the risk of catastrophic loss due to flooding.

“Catastrophes cannot be predicted, but can certainly be avoided,” Bothwell says. He claims a commercial grade sump pump from his company is a better form of insurance than a policy, since some insurance plans do not even include flooding in their coverage.

“Why not take preventive measures?” he asks. “Be a smart businessman and prevent the damage before it can even happen; buy an industrial sump pump.”

Summer 2018 Back Issue

$4.95

Livable Basements

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|