A biomedical building on the campus of the University of Florida in Gainsville was showing signs of foundation failure.

There were visible stress stair-step cracks in the brick veneer, the veneer was pulling away from the building and a large crack developed inside a classroom floor. It was determined a sizable void had developed under the concrete slab flooring in the classroom which allowed the fracture to occur.

Foundation Professionals of Florida, based in nearby Lake City was contracted to solve the problem.

David Brown, vice president at FPI says, “The purpose of this job was to stabilize the foundation, fill voids below the concrete slab classroom floor and structurally seal the cracks in the concrete floor.” The solution would require multiple technologies, including push piers, polyurethane grout and structural epoxy.

Work began in 2019, and the first step was to stabilize the foundation, which involved installing steel push piers from ECP. Push piers, often referred to as resistance piers, are driven deep into the soil to lift and support weak foundations for commercial buildings and residential structures. Mike Malina, director of marketing at ECP says, “ECP steel push piers are the most common foundation repair product used today. It is the standard for all piering methods in the foundation repair industry and the top choice for professional foundation repair contractors.”

FPI excavated near the load bearing walls of the classroom, then drove the hydraulically advanced galvanized steel push piers to load-bearing strata, attached the piers to brackets and raised the building to the most feasible elevation. Angle iron spreader beams distribute the load to the new pile foundation.

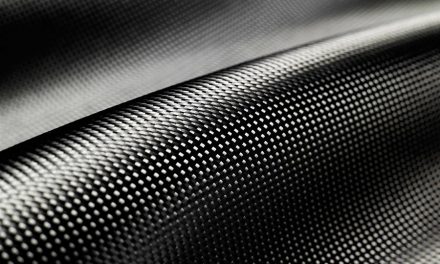

Next, crews addressed the voids beneath the slab. “We filled the void below the classroom concrete structure slab using Precision Lift two-component polyurethane grout,” Brown says. “Our structural grouts are used for concrete slab lifting and raising, undersealing concrete slabs, compaction grouting of soil, and filling voids behind pipes, walls, manholes and other structures.”

The closed-cell high-density structural foam from Prime Resins can be used in wet or dry environments, and is strong enough to support structures. “One benefit of our polyurethane grout injection is stabilizing the soil to reduce the potential for future settling and also lifts any low spots that may have started to sink,” says Brown.

With the building supported and voids filled, FPI repaired the structural crack in the classroom floor, again using a Prime Resins product. “We used a specialized epoxy gel resin and pressure injection,” he says. “We drilled numerous injection ports along the crack, thoroughly cleaned and installed injection ports. A surface sealant was applied before the injection of the high-strength low-viscosity epoxy.”

He concludes, “Grouting and piering is a versatile solution that can be used in many different situations, including sinking or cracked foundations, shifting veneers, stair-step cracks, driveways, parking lots, and other structural problems.”

Summer 2020 Back Issue

$4.95

Grouts for Waterproofing and Structural Repair

The Crawlspace: Link to a Healthy Home

Waterproofing Your Crawlspace

High Performance Crawlspace Liners

Working In an Era of Covid

Elastomeric Coatings: Misconceptions, Myths, and Key Considerations

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Grouts for Waterproofing and Structural Repair

Grouts can repair leaking manholes and sinking foundations, being injected into or behind the failure to eliminate moisture or restore structural strength.

The Crawlspace: Link to a Healthy Home

By André Lacroix

Encapsulating the crawlspace, conditioning it, and providing exhaust ventilation can create a healthy crawlspace.

Waterproofing Your Crawlspace

By Ben Rogers

Waterproofing, proper monitoring, and air quality control, can make crawlspaces a healthy, usable, and more pleasant area of the home.

High Performance Crawlspace Liners

By Ryan McCoy

High performance membranes can be used to encapsulate crawlspaces to improve air quality, energy bills, and the risk of mold and mildew.

Working In an Era of Covid

By Diana Parks

As the coronavirus spreads and threatens to derail construction projects, a legal expert explains how the industry can prepare for its effects.

Elastomeric Coatings: Misconceptions, Myths, and Key Considerations

By Chadwick Collins

Fluid-applied roof membranes made of high-tech resins cure to form a rubber-like elastomeric waterproof membrane that greatly prolongs the life of the roof.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|