By Patrick Nevison, P.E.

Photos courtesy of Safe Basements

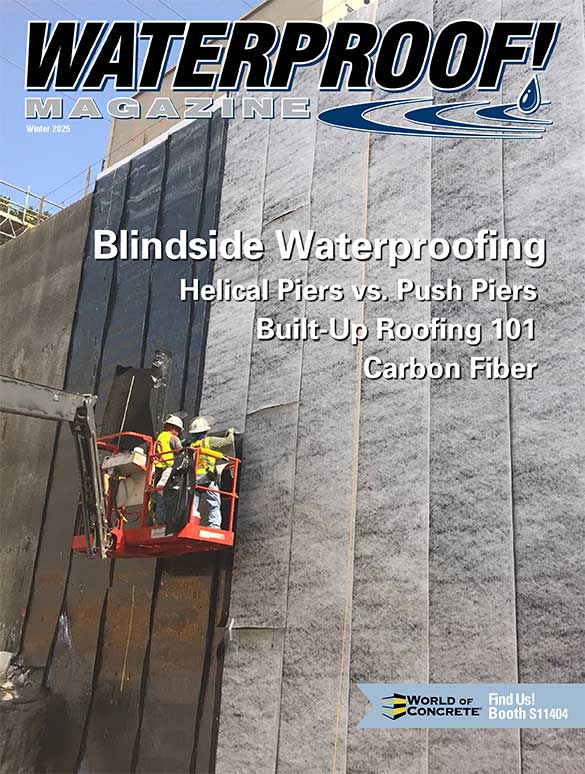

Grain storage building walls pushed back to plumb with steel buttresses supported by SafeBase helical piers and footings lifted and rotated with SafeBase push piers.

Installing steel pilings with brackets to support the footings on deep foundations is a typical repair method for settling foundations. Here, we’ll take a close look at helical piers and push piers, and explore the differences and uses of each type of foundation repair system.

Signs of Foundation Settling

Signs of settlement may include vertical, diagonal, or stair-step cracks through the foundation walls. There may also be uneven floors, doors, and windows that do not function properly and cracks in other interior finishes. When evaluating a structure for settlement issues, it is important to use measuring equipment to verify which portions of the foundation are sinking, and how much.

Typically laser levels or zip levels are used to take elevation measurements along the perimeter of the structure and at the location of interior footings. This allows the building to be mapped out and see how much lift is needed in each area to bring it back to level. This step is critical as it can prevent possible misdiagnosis from simply reading cracks.

Push vs. Helical Piers

Once the structure is mapped out, a repair plan can be made typically using push piers or helical piers. The main difference between push piers and helical piers is the method of installation. Push piers are hydraulically driven into the ground using the weight of the structure as resistance. Helical piers are screwed into the ground using a hydraulic torque motor. After the piling is installed, both behave in a similar manner. A steel bracket is supported by the piling and the bracket supports the footing. Both push piers and helical piers may be used to lift the structure back to level and prevent future settlement.

Push Pier Benefits

Push piers are great for repairs so long as the structure has enough weight to resist the force required to drive the piers into the ground. Push piers are installed by placing a bracket under the footing and attaching a hydraulic ram to the bracket, then pressing sections of steel tubing into the soil. The sections of steel tubing have an internal coupler that slides inside the previously installed section. Sections of tubing are typically pushed into the ground until refusal. A hydraulic pressure gauge is ran inline with the cylinder so the driving force can be monitored during installation. At the end of the installation, the hydraulic pressure is held on the pier, load testing the pier at the final depth.

Push pier installation in a basement (top) and lifting the foundation of a Minneapolis home from inside the crawlspace (bottom). This was a lift of more than 12 inches, performed by SafeBasements of Minnesota, January 2021.

Installation Methods

Helical piers are driven independently of the structure and attached with a bracket after installation. A lead section with helix flights is placed near the foundation and attached to a drive head typically operated by a mini-excavator or skid steer, and screwed into the ground. Hand-held installations are possible as well. Extensions are then bolted onto the lead and screwed into the ground. Differential pressure gauges and torque charts from the drive head manufacturer, or other torque measuring equipment, are used to correlate torque to bearing capacity of the pier. The pier is screwed in until the required capacity is achieved.

It is best to have the capability of installing both push piers and helical piers to take advantage of either product for the right situation. Some projects will benefit from using both push piers and helical piers. Typically, the material cost for push piers is less than that for helical piers assuming the same depth is required to achieve the required bearing capacity, which may result in a more cost-effective solution for the property owner. Each push pier is load tested during installation, so the actual capacity is verified on every pier. Push piers use relatively small handheld installation equipment and can be installed in areas with limited access such as crawlspaces, or inside basements. Helicals can be installed with handheld equipment, but it is much more cumbersome than the push pier installation.

Helical piers can be installed adjacent to existing structures to retrofit with repair brackets or can be installed for new construction. Push piers cannot be installed for new construction without special pile-driving equipment. Rhino Foundation Systems, in Utah, has proprietary Slam Pier equipment which has been successfully used on projects to drive SafeBase push piers, for new construction and retrofit applications. Helical piers can have the flight configuration adjusted to match the soil profile to optimize installation depth, whereas push piers are typically driven to refusal on bedrock or other competent bearing strata.

SafeBase helical pier installation to support a new foundation (top). Hand-held tieback installation (bottom).

As a general rule of thumb, if you have to ask if it is too light to use push piers, use helical piers. Helical piers will work regardless of the weight of the structure and in most soil conditions. Push piers may begin to lift the structure prior to advancing the pier to suitable strata if there is not enough weight. Typically, if there is a basement or frost foundation, push piers will be fine to use. If it is a shallow footing or thickened edge slab, helicals may be needed.

Helical piers can also resist tension forces which push piers cannot, without field welding or other special manipulation. Helical piers can be used in tension application for tiebacks, soil nails, or in vertical or battered pilings. Helical piers can also be attached to push piers for lateral restraint, using the push pier to support the footing vertically and the helical pier to resist lateral forces with a bracket adapter.

Many successful projects have been completed with both push piers and helical piers. Contractors may have preferences to use one over the other for different situations, or both for the right project.

Winter 2025 Back Issue

$4.95 – $5.95

Trade Show Preview

Blindside Waterproofing: Techniques, Challenges, and Advancements

Foundation Repair Using Push Piers And Helical Piers

The Commercial Built-Up Roofing (BUR) Systems

Built-Up Roofing 101 from CertainTeed

Description

Description

Trade Show Preview

Explore waterproofing-related businesses and educational sessions at the upcoming trade shows, including World of Concrete.

Blindside Waterproofing: Techniques, Challenges, and Advancements

By Vanessa Salvia

In urban construction and infrastructure projects, space constraints often necessitate innovative building techniques. One such method, blindside waterproofing, has become increasingly prevalent in recent years.

Foundation Repair Using Push Piers And Helical Piers

By Patrick Nevison, P.E.

This article takes a close look at helical piers and push piers, and explores the differences and uses of each type of foundation repair system.

The Commercial Built-Up Roofing (BUR) Systems

By Rose Morrison

Built-up roofing systems offer various options to meet different building needs and environmental conditions, with benefits that few other roofing types can match.

Built-Up Roofing 101 from CertainTeed

By Abby Feinstein and Ted Winslow

Built-up roofing or BUR consists of multiple layers of hot asphalt being applied between ply sheets thereby building up a waterproof roof assembly.

Carbon Fiber: The New Standard in Structural Repair for Basements

By Vanessa Salvia

In recent years, the field of basement and foundation repair has seen a significant shift towards carbon fiber technology.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |